|

|

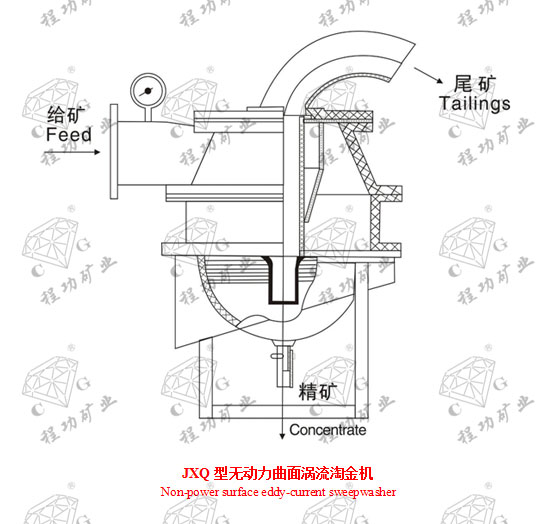

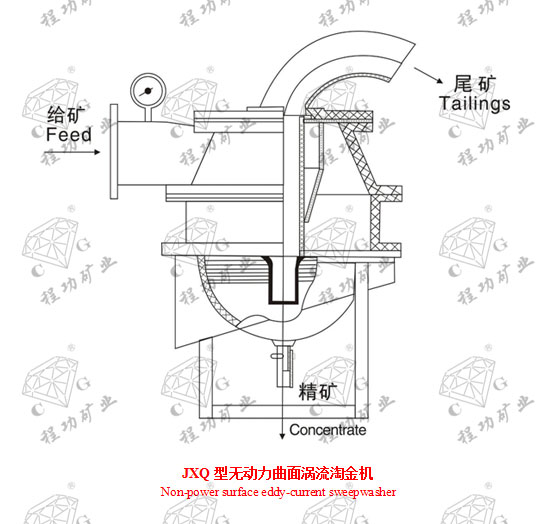

JXQ型无动力曲面涡流淘金机

Non-power surface eddy-current sweepwasher

利用给矿高差产生的压力使矿浆从给矿管以切线方向进入机内,通过强压稳流环,迫使矿浆作旋转运动,产生较强的旋转流,离心力、摩擦阻力。当旋转流往下运动到底盘时,金粒首先进入底盘的渐开线和螺旋线沟槽内,随着旋转矿浆的带动,金粒和重矿物沿沟槽底端中心流动,聚集在底端平面上并从精矿管排出。尾矿在轴向力的作用下从溢流管排出腔外。该设备对矿浆浓度及给矿压力变化适应性强,不需动力,与其他设备比较对细粒金分选效果好。

The pulp delivered form feed pipeline flows into the sweepwasher in the direction of tangent line via the pressure pro-duced by difference in height of feed pulp level.The pulp is forced to do rotary motion via barretter with strong pressure.The motion produces strong rotary flow,centrifugal force and frictional force.When the rotary flow moves downward to the bottom disk,gold grain will firstly enter into the ditch of involute and helix on the bottom disk.Gold grain and heavy minerals will flow along the bottom center of ditch with the motion of spiral pulp.They will be concentrated on the flat surface of the bottom and be discharged by concentrate pipeline.The tailings sand will be discharged by overflow pipeline under the action of axial force.The equipment has good adaptability to the change of pulp concentration and feed pressure.Power is unde-sirable in the equipment.Compared with other equipment,the equipment has good beneficiation effect on fine-grain gold.

型号规格

Model |

JXQ300 |

JXQ400 |

JXQ600 |

JXQ900 |

JXQ1200 |

适用范围 |

原矿品位

Feed Grade |

t/g |

0.66-0.32 |

0.66-0.32 |

0.66-0.32 |

0.66-0.32 |

0.66-0.32 |

砂金、尾矿金、

重矿物、扫洗再选

Sccpe of application

Sand gold,tailings gold,heavy minerals, scavenging and recleaning |

给矿浓度

Feed Concentration |

% |

<25 |

<25 |

<25 |

<25 |

<25 |

给矿粒度

Feed Size |

mm |

<3 |

<3 |

<5 |

<6 |

<6 |

给矿压力

Feed Pressure |

Mpa |

<0.1 |

<0.1 |

<0.1 |

<0.1 |

<0.1 |

| 给矿高差 Feed Difference in Height |

M |

0.5-6.5 |

0.5-6.5 |

0.5-6.5 |

0.5-6.5 |

0.5-6.5 |

| 回收率 Recovery |

% |

97-78 |

97-78 |

97 |

78 |

97 |

| 补加水量 Replenished Water Quantity |

L/min |

6-13 |

6-13 |

6-16 |

6-16 |

6-18 |

| 处理量Capacity |

m3/h |

20-60 |

30-80 |

40-100 |

60-160 |

80-180 |

| 重量Weight |

kg |

170 |

190 |

280 |

380 |

490 |

注:机器采用内衬耐纳特橡胶或玻璃钢、聚氨脂制造,耐磨防腐。

Remark:The equipment is manufactured by using LINATEX rubber or glass fiber reinforced plastics as interna lining with the properties of anti-friction and anti-corrosion.

| |