|

PLC-7000浮选机全自动控制系统

Flotation

Machine Fully Automatic Control System

该系统可应用于金属矿山、非金属矿物的浮选作业流程中,以入浮矿浆浓度、药剂添加量和浮选槽液位作为主要控制内容,以提高浮选精矿品位和回收率并降低生产成本作为控制目标。

This system can be used in flotation of metallic minerals and

nonmetallic minerals. It mainly controls the concentration of flotation slurry,

reagent added volume and the liquid level of flotation tank, and aims to

improve the grade and recovery ratio of flotation concentrate, as well as

reduce production costs.

控制内容

Control Content

1.实时检测原矿浆的浓度和流量,通过PID定值法运算改变自动阀开度调整稀释水流量,使入浮矿浆稳定在设定范围

1. Conduct real-time detection of concentration and flow of the

original slurry. Change the openness of automatic valve and adjust the dilution

water flow through PID constant value method to stabilize flotation slurry

within the setting range.

2.根据入浮干矿量自动调节入浮前的浮选药剂添加量(一段加药)

2. Automatically adjust the adding amount of flotation reagent

before flotation according to flotation dry ore (adding reagent in phase I).

3.根据浮选工艺阶段的具体要求优化控制浮选指标,自动调节各个浮选槽药剂添加量(二段加药)

3. Optimize flotation indexes according to specific requirements

of flotation stage and automatically adjust the adding amount of reagent in

each flotation tank (adding reagent in phase II)

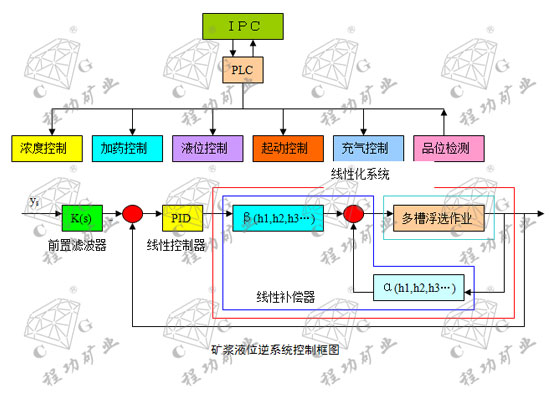

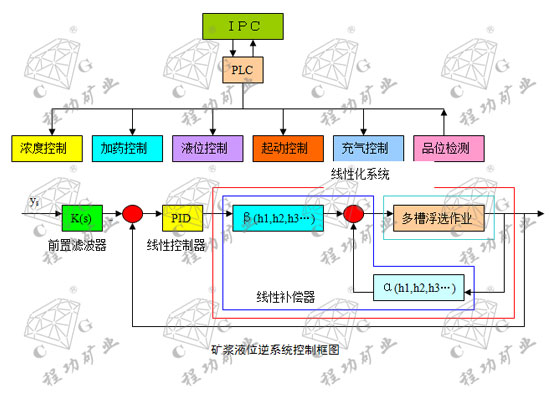

4.检测浮选槽液位水平,根据浮选阶段调控指标通过逆系统控制方法自动调节槽间闸门位置,闭环控制液面稳定在所需的范围

4. Detect the liquid level of flotation tank; regulate indexes

according to flotation stages; automatically adjust strobe position between

tanks through inverse system control method; stabilize the liquid level of

closed-loop control within required range.

5.对于充气式浮选机可根据需要进行浮选槽充气量控制,保障浮选效果

5. For aeration flotation machine, aeration quantity of flotation

tank can be controlled according to needs to ensure flotation effects.

控制方案

Control Scheme

通过检测给入矿浆浓度和流量调节加水阀的流量入浮矿浆浓度稳定在设定值;依照浮选各个阶段的不同要求精确控制加药量;根据工艺设定采用逆系统方法控制浮选机液位决定浮选泡沫刮出量,根据液位控制中间过程补水量;根据在线品位检测数据分析运行状态,便于及时调整工艺指标。

Adjust the flow of filling valve through detecting the

concentration and flow of feeding slurry, stabilize the concentration of

flotation slurry within the setting value, accurately control the additional

dosage according to different requirements in different flotation stages; adopt

inverse system method to control the liquid level of flotation machine and decide

the scraping amount of flotation froth according to technological design,

control water supplement amount during intermediate process according to liquid

level, detect the running status of data analysis according to online grade for

timely adjustment of technological indexes.

![矿浆液位逆系统控制框图]()

系统功能

System Function

1.系统具有任意转换操作自动/手动操作,在操作界面上修改入浮浓度、各点加药量、补水量、浮选槽液位等控制参数

1. The system is equipped with functions of any conversion

operation and automatic/manual operation. It can change control parameters such

as flotation concentration, additional dosage of each point, water supplement

amount, and liquid level of flotation tank.

2.系统可根据需要修改各浮选槽驱动电机的起动方式

2. The system can change the start mode of drive motor in each

flotation tank based on requirements.

3.实时显示原矿浓度、原矿流量、入浮浓度、各点加药量、液位高度等参数

3. The system can instantly display the values of parameters such

as the concentration of raw ore, the flow of raw ore, flotation concentration,

additional dosage of each point, height of liquid level.

4.实时进行各测控参数运行趋势图,便于及时进行工艺调整

4. The system can conduct real-time monitor of the operation tendency

chart for each parameter so that technological adjustment can be made in time.

5.系统自动完成各运行参数的历史数据记录并进行数据统计和分析

5. The system automatically finishes the historical data records

of each operating parameter and conducts data statistics and analysis.

6.系统根据控制目标自动调整浮选作业运行在最佳工况状态

6. The system automatically adjusts the flotation operation

according to control objectives to get it under optimum working conditions.

7.可打印输出各种数据报表和趋势图,可上传至企业管理层

7. The system can print out all kinds of data reports and tendency

charts which can be uploaded to the management of enterprise.

8.具有各参数上下限和电机故障报警功能

8. The system is equipped with alarm functions for upper and lower

limit of each parameter and motor faults.

9.系统可接入企业局域网,组成工厂自动化系统

9. The system can connect enterprise local area network to

constitute factory automation system.

系统构成

System Structure

工控机或触摸屏及PLC系统

Industry control computer or touch screen

and PLC system

1.自动控制用户界面

1. Automatic control user interface

2.自动液位控制子系统

2. Automatic liquid level control subsystem

3.数控加药子系统

3. Numerical control reagent adding subsystem

4.矿浆浓度计

4. Slurry concentration meter

5.电磁流量计

5. Electromagnetic flow meter

7.数控流量阀

7. Numerical control flow valve

使用效果

Using Effect

浮选自动控制可以改善操作条件和保护环境,避免人为因素造成的浮选作业系统不稳定的现象。可以在降低药耗、电耗的基础上,稳定产品质量并提高浮选矿物回收率使用该系统可以达到减员增效的目的,降低了操作人员的劳动强度。

Flotation automatic control can improve operating conditions,

protect environment, and avoid instability of flotation system caused by human

factors. It can stabilize product quality and improve the recovery ratio of ore

flotation on the basis of reducing reagent consumption and power consumption.

If this system is adopted, the purpose of fewer labors but higher efficiency

can be achieved. The labor intensity of operators can be reduced.

用户可选功能模块

Function Modules for Users’ Choice

1.上位机系统:含计算机、组态软件、输入输出及通讯设备

1. Upper computer system: Including computer, configuration

software, input devices, output devices, and communication devices

2.下位机系统:PLC软硬件系统及其功能模块

2. Lower computer system: PLC software and hardware systems and

their function modules

3.自动加药功能模块

3. Function module of automatic reagent adding

4.浮选槽液位控制功能模块

4. Function module of control over liquid level in flotation tank

5.入浮浓度和补水量自动控制模块

5. Automatic control module of flotation concentration and water

supplement amount

6.充气式浮选机充气量自动控制模块

6. Automatic control module of aeration quantity of aeration

flotation machine

7.浮选槽电机软起动功能模块

7. Function module of motor soft starting of flotation tank

|