|

试验室XMQ型手动板框压滤机技术参数

Technical Parameters of Laboratory Plate and Frame Filter Press

一、概述

I. Introduction

板框压滤机是一种间歇操作的加压过滤设备,适用于各种悬浮液的固液分离。它是由滤板的滤框(板框式)组成或由滤板排列(厢式)组成滤室,在输料泵的作用下,把悬浮液(料液)压入各个滤室,再利用过滤质介质(常用滤布,也可用滤纸、滤膜等)把固体和液体分离开来。厢式又有普通滤板和隔膜板之分。压滤机广泛适用于石油、化工、制药、制糖、冶金、食品、陶瓷、淀粉、洗煤、染料、油漆及各行业的污水处理等领域。

Plate and frame filter press is a kind of pressure filtration equipment that works intermittently. It applies to solid-liquid separation of various kinds of suspension. Its filter chamber is composed of (plate-frame type) filter frames of filter plates or composed of arranged (chamber-type) filter plates. Under the action of delivery pump, press the suspension (feed liquid) into each filter chamber. Then use filter media (usually filter cloth, sometimes filter paper, filter membrane, etc) to separate the solid from the liquid. The chamber-type filter plates are then divided into common filter plates and diaphragm plates. The filter presses are widely used in the fields of petroleum, chemicals, pharmacy, sugaring, metallurgy, food, ceramics, starch, coal washing, dyeing, and painting and for sewage treatment in various industries.

压滤机系列有320、450、630、800、1000、1250、1500、Φ800、Φ1000型板框式及厢式,过滤面积0。5㎡-500㎡。板框材质有铸铁、球铁、增强聚丙烯、玻璃纤维聚丙稀(耐温120℃)及不锈钢等。压紧形式有手动压紧、千斤顶压紧、机械压紧、液压压紧、自动保压压紧及先进的微机程控全动控制等。过滤形式有明流、暗流、明流可洗、暗流可洗和双向交叉洗涤。聚丙烯材质具有化学性能稳定、耐酸碱、耐腐蚀、无毒、无味、无污染、操作轻便等特点。

The filter press series have 320, 450, 630, 800, 1000, 1250, 1500, Φ800, and Φ1000 plate-frame type and chamber-type ones. Their filtering area is 0.5㎡ to 500㎡. The plate frame can be made of cast iron, spheroidal graphite cast iron, reinforced PP, glass fiber PP (abele to endure the temperature of 120℃), stainless steel, etc. The pressing forms include manual pressing, jack pressing, mechanical pressing, hydraulic pressing, automatic maintaining pressure pressing, and advanced minicomputer program control automatic control. The filtering forms include open flow, undercurrent flow, open flow that can be washed, undercurrent flow that can be washed, and two-way cross-washing. Polypropylene materials have characteristics such as stable chemical property, acid-alkali resistance, corrosion resistance, no toxin, no taste, no pollution, and easy operation.

本公司生产的系列压滤机均符合国家和行业有关标准规定,也可按用户需要,生产特种型号和规格的压滤机产品。

The series of filter press manufactured by this company conform to relevant national and industrial standards. We can also provide filter press products of special models and specifications according to the requirements of users.

二、技术参数

II. Technical Parameter

手动千斤顶压紧增强聚丙烯板框式压滤机

Manual jack pressing reinforced PP plate and frame filter press

型号规格

Model |

过滤面积Filter area |

框内尺寸

Frame size |

滤饼厚度

Cake thickness |

滤板数量

Quantity |

滤框数量

quantity |

滤室容积

Filter chamber volume |

外形尺寸

Overal dimension |

过滤压力

Filtration pressure |

质量

Weight |

| ㎡ |

mm |

mm |

pcs |

pcs |

L |

mm |

Mpa |

kg |

| XMQ1/320-25U |

1 |

320×320 |

25 |

4 |

5 |

15 |

1105×

570×640 |

0.8 |

290 |

| XMQ2/320-25U |

2 |

320×320 |

25 |

9 |

10 |

31 |

1405×

570×640 |

0.8 |

328 |

| XMQ3/320-25U |

3 |

320×320 |

25 |

14 |

15 |

46 |

1705×

570×640 |

0.8 |

350 |

| XMQ4/450-30U |

4 |

450×450 |

30 |

9 |

10 |

61 |

1700×

700×950 |

0.6 |

656 |

| XMQ6/450-30U |

6 |

450×450 |

30 |

14 |

15 |

91 |

2000×

700×950 |

0.6 |

699 |

| XMQ8/450-30U |

8 |

450×450 |

30 |

19 |

20 |

121 |

2300×

700×950 |

0.6 |

752 |

| XMQ10/450-30U |

10 |

450×450 |

30 |

24 |

25 |

152 |

2600×

700×750 |

0.6 |

806 |

| XMQ12/450-30U |

12 |

450×450 |

30 |

29 |

30 |

182 |

2900×

700×950 |

0.6 |

859 |

| XMQ16/450-30U |

16 |

450×450 |

30 |

39 |

40 |

243 |

3500×

700×950 |

0.6 |

965 |

| XMQ15/630-30U |

15 |

630×630 |

30 |

18 |

19 |

226 |

2520×

980×1180 |

0.6 |

1316 |

| XMQ20/630-30U |

20 |

630×630 |

30 |

24 |

25 |

298 |

2880×

980×1180 |

0.6 |

1397 |

| XMQ25/630-30U |

25 |

630×630 |

30 |

31 |

32 |

381 |

3300×

980×1180 |

0.6 |

1470 |

| XMQ30/630-30U |

30 |

630×630 |

30 |

37 |

38 |

452 |

3660×

980×1180 |

0.6 |

1570 |

三、结构与使用说明

III. Structure and Instruction

压滤机由四部分组成,即主机架部份、过滤部份、压紧部份和控制系统。

Such filter press consists of four parts, i.e. main frame part, filtering part, pressing part, and control system.

1、主机架部分

1. Main frame Part

机架是设备的基础,用于支撑过滤结构与连接其他部件。它由止推板、压紧板、压紧架、主梁等部件组成。工作时,压紧架(或油缸)的丝杠(或活塞杆)在压力的作用下,顶紧压紧板与滤板、滤框、滤布,保证料液在滤室内不漏液地进行加压过滤。

The main frame is the basis of equipment which is used to support the filtering structure and connect other parts. It is composed of thrust plate, pressing plate, pressing frame, girder, etc. During operation, the lead screw (or piston rod) of pressing frame (or hydro-cylinder), under the action of pressure, jack up the pressing plate and filter plate, filter frame, and frame cloth, to ensure the feed liquid can be pressurized and filtered without any leakage in the filter chamber.

2、过滤部分

2. Filtering Part

过滤部分由若干块滤板、滤框组成,且按一定顺序排列在主梁上,滤板与滤框之间夹着滤布。

The filtering part is composed of several filter plates and filter frames which are arranged on the girder in certain order. Between the filter plate and filter frame is clipped filter cloth.

物料从止推板上的进料孔进入各滤室,固体颗料因粒径大于过滤介质的空隙而被截流在滤室内,并形成滤饼,液体则通过滤布从液孔排出,出液方式有明流、暗流。每个滤板下方有一个出液孔,并装有水咀,这种从每块滤板水咀排除的方法叫明流;若把各块滤板的滤液汇合在一起,由一个出液通道排除机外,这种形式叫暗流。

The materials enter each filter chamber from the feeding mouth in the thrust plate. The solid particles are intercepted in the filter chamber since its particle diameter is larger than the gap of filter media and then form filter cake. The liquid is discharged from the liquid hole through the filter cloth. Liquid can be discharged through flow and undercurrent flow. There is a discharge hole below every filter plate. Besides, it is equipped with nozzle. Such method of discharging from the nozzle of every filter plate is called open flow. The filtering method of discharging out of the machine through a discharging passage when the filter liquid from each filter plate converges is called undercurrent flow.

压滤机根据是否需要洗涤滤饼又可分为可洗和不可洗两种形式。需进行洗涤滤饼的称可洗型,反之称为不可洗型。可洗型的滤板有两种形式,一种板上开有洗涤液进孔,称为有孔滤板(也称为洗涤板);另一种未开洗涤液进孔,称为无孔滤板(也称非洗涤板)。可洗型又有单向洗涤和双向(交叉)洗涤之分。单向洗涤的滤板,有孔滤板和无孔滤板间隔放置;双向洗涤的滤板,都为有孔滤板,但相邻两块滤板的洗涤孔应错开,可洗分为明流可洗和暗流可洗,明流可洗是在止推板与滤板上设有希液孔,穿过滤饼,从无孔滤板排除,双向洗涤时,先从压滤机侧洗液进行单向洗涤,然后环另一侧进行洗涤,明流可洗适于无污染、无气味、无毒、不挥发的物料。

The filter presses can be divided into washable filter presses and unwashable filter presses based on whether it is necessary to wash the filter cake. The filter presses for which the filter cake needs to be washed are called washable filter presses. Otherwise, they are called unwashable filter presses. There is one kind of plate in which inlet opening of washing liquid is designed. Such kind of plate is called filter plate with hole (or washing plate). There is the other kind of place in which inlet opening of washing liquid is not designed. Such kind of plate is called filter plate with no hole (or non-washing plate). The washable ones are then divided into one-way washable ones and two-way (crossing) washable ones. The one-way washable filter plates, filter plates with holes, and filter plates with no holes shall be placed one by two. Two-way washable filter plates are all filter places with holes. However, the washing holes of two neighboring filter places must be staggered. Washable ones are divided into open flow washable ones and undercurrent flow washable ones. Open flow washing refers to such process: Liquid holes are designed on the thrust plate and filter plate; the liquid passes the filter cake and is discharge from the filter plate with no hole. During two-way washing, first wash liquid from the side of filter press (one-way wash); then wash it from the other side. Open flow washing applies to materials that are pollution free, odorless, nontoxic, and non-volatile.

暗流可洗,此种形式的进料和洗涤与明流可洗一样,只有出液方式不同,各块滤板的料液经出液通道汇集在一起排出。暗流可洗适应于易挥发、有毒、有害气体的物料使用。

Undercurrent flow washable: The feeding and washing with undercurrent flow washing are similar to that with public flow washing. Only the liquid discharging methods are different. With this type, the feed liquid from each filter plate passes the discharging passage and converges before it is discharged. Undercurrent flow washable applies to materials that are easily volatile, toxic and harmful.

明流不可洗,但需全部无孔滤板。此种形式只有一个进料通道,物料进入各滤室,液体通过从各块滤孔排出。

Open flow unwashable: With this type, all filter plates shall be free of hole. There is only one feeding passage with such type. The materials go into each filter chamber and liquid is discharged from each filter hole.

暗流不可洗,但需全部用无孔滤板。该形式有进料通道和出液通道,各滤板的液体汇集于一个通道排出。

Undercurrent flow unwashable: With this type, all filter plates shall be free of hole. There is both feeding passage and discharging passage with this type. The liquid from each filter plate converges in one passage and is then discharged.

隔膜压榨式压滤机是在普通厢式基础上,用一部份隔膜板代替普通滤板,间隔放置于普通滤板之间,在过滤、洗涤后,压缩气体充入隔膜板鼓起隔膜(橡胶或聚丙烯),压榨滤饼,使其含液率显著降低,提高分离效果。压榨压力一般高于过滤压力0.1Mpa,压榨时放气阀关闭,过滤时必须开放气阀。隔膜压榨压滤机也分明流、暗流,其洗涤、吹干等结构原理与普通厢式压榨机相同。

Membrane-type filter press is a kind of filter press developed from the common tank-type one. It replaces the common filter plates with some diaphragm plates which are placed between the common filter plates one by two. After filtration and washing, compressed air is inflated into the diaphragm plate to get the diaphragm (rubber or polypropylene) to bulge. Press the filter cake to get its liquid ratio to decrease significantly and improve separation effects. The pressing pressure is usually higher than the filtration pressure 0.1Mpa. The air-release valve must be shut during pressing but it must be opened during filtration. There is also open flow and undercurrent flow for membrane-type filter press. Its working principle for washing, drying, etc is the same as that of common tank-type filter press.

在压滤机使用过程中,过滤介质(即滤布等)起着关键的作用,滤布性能及选型正确与否直接影响着过滤效果。目前所使用的滤布中最常用的是否成纤维经纺织而成滤布,其材质可分为涤纶、维纶、丙纶、棉纶等,还包括棉纺布、无纺存、筛网、滤纸、微孔膜等。由于滤布材质及编织方法不同,其强度、伸长率、通气性、厚度、耐酸碱度物理化学性能也不均相同。用户可根据料浆的颗粒度、密度、粘度、酸碱度、化学成分和过滤额定工艺条件来选择,以期达到理想的截留效果和过滤速度。滤布在用过一段时间后,其网眼会被物料的细微颗粒堵塞,从而影响过滤效率,所以滤布应定期进行冲洗,使其再生或更换。

During the use of filter press, the filter medium (such as filter cloth) plays a critical role. Whether the performance and type of filter cloth are correct directly affects filtration effects. Among all those types of filter cloth being currently used, the most common one is textile filter cloth made of synthetic fiber. Its materials include cotton spinning cloth, nonwoven cloth, screen mesh, filter paper, microporous membrane, etc. Since the materials and knitting methods of filter cloth are different, their physical and chemical properties such as strength, elongation degree, air permeability, thickness, acid-resistance, and alkali-resistance also vary. The user can choose it according to the granular size, density, viscosity, pH value, chemical composition, and rated technological conditions of filtration of slurry, so as to get ideal interception effect and filtration speed. After the filter cloth has been used for a period of time, its meshed may be blocked by fine grains of materials, so as to affect filtration efficiency. Therefore, the filter cloth shall be flushed on a regular basis for reproduction or replacement.

3、压紧部分

3. Pressing Part

压紧形式分手动压紧、千斤顶压紧、机械压紧、液压压紧、自动保压压紧。

Pressing forms are divided into manual pressing, jack pressing, mechanical pressing, hydraulic pressing, and automatic pressure keeping pressing.

(1)手动压紧和千斤顶压紧

(1) Manual Pressing and Jack Pressing

手动压紧是小齿轮传动大齿轮达到顶压压紧板的作用,在小齿轮上利用杠杆从小齿轮传动大齿轮丝杠。一般一人力量即可。千斤顶压紧为直接压紧。

Manual pressing is a pressing form where the small gears drive the big gears so as to jack up the pressing plate. Use lever on the small gears to drive the screws of big gears from the small gears. Usually, this can be realized with the force of only one person. The pressing of jack is direct pressing.

(2)机械压紧

(2) Mechanical Pressing

机械压紧是靠电动机通过减速机,带动大齿轮丝杠达到顶紧压紧板,前进或倒退靠正反开关作用。这种形式压紧力不能够直接显示,由电器控制柜自行控制,当电机电流接近额定电流时自动停机,出厂前已调试合适。

With mechanical pressing, the motor drives the screws of the big gear through speed reducer, to jack up the pressing plate. Its forward or backward movement is realized through direct-reverse switch. For the pressing method, the pressing force can not be directly displayed and is automatically controlled by the electric control cabinet. When the motor current approximates the rated current, the machine stops working automatically. It shall be properly debugged before leaving the factory for shipment.

(3)液压压紧

(3) Hydraulic Pressing

液压压紧系统由电动机带动油泵,压力油经控制阀进入油缸,由活塞、活塞杆顶紧或拉开压紧板而实现。控制方式分为手控式、电控式、自动保压式和程控自动拉板式四种。

For hydraulic pressing system, the motor drives the oil pump. The pressure oil enters the hydro-cylinder through the control valve. Pressing is realized when the piston and piston rod jack up or pull out the pressing plate. There are four kinds of control method, manual control, electric control, automatic pressure keeping control, and program control automatic tie-plate type control.

手动式为压紧板的压紧与拉开,靠手拉手动换向阀4来实现。压紧时,把换向阀推向压紧位置达到额定压力后,用丝杆上的锁紧螺母锁紧,然后将阀推向中间位置,关闭电动机,开始过滤。当过滤、洗涤等程序结束后,启动电动机,应先把换向阀推向压紧位置,松开丝杆锁紧螺母后再退,即可打开滤板卸掉滤饼。高压溢流阀3和抵压溢流阀5在出厂前已经调试适当,工作中不允许任意调整,以免损坏零部件。

Manual control is pressing and pulling of pressing plate which is realized by pulling hand-control directional valve by hand. During pressing, push the directional control valve 4 to the pressing position. After the rated pressure is rated, lock it with lock nuts on the lead screws; then push the valve to the central position, shut down the motor, and begin to filter it. After the programs such as filtration and washing are finished, start the motor. First push the direction control valve to the pressing position; loosen the lock nuts on the lead screws and then move backward. Then the filter plate can be opened and the filter cake can be dismantled. The high pressure overflow valve 3 and low pressure overflow value 5 have been debugged properly before leaving the factory for shipment. They can not be adjusted without permission, so as to avoid their parts.

电控式仅把换向阀4由手动换向阀换为电磁换向阀,工作中只需按动按钮,其他操作程序与手控式相同。

The electric control type only changes the direction control valve 4 from manual direction control valve to electromagnetic directional valve. During operation, only the button needs to be pressed. Other operation processes are the same with those for the manual control type.

(4)自动保压式或程控自动拉板式为压滤机在压紧过滤过程中,不需用丝杆锁紧螺母保压,而靠控制系统自动控制。

(4) For the automatic pressure keeping type and program control automatic tie-plate type, there is no need to lock the nuts with lead screws for pressure retention during the pressing and filtration processes of filter press. Only automatic control by the control system is needed.

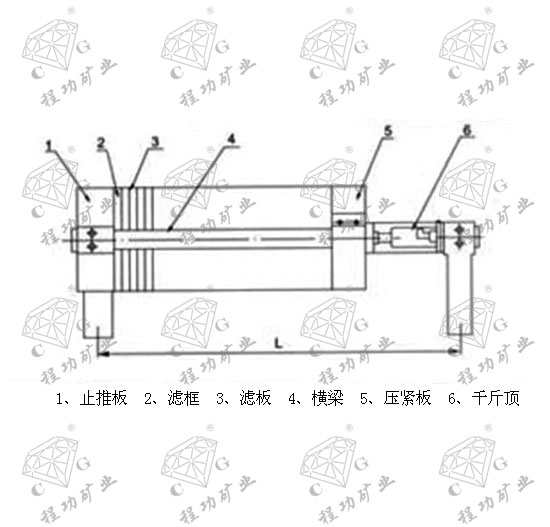

1. Thrust plate 2. Filter frame 3. Filter plate 4. Girder 5. Pressing plate 6. Jack

|