|

试验室FX3-8型封闭试样自动缩分器技术参数

Technical Parameters of Laboratory type of enclosed automatic sample splitting

FX3-8封闭式试样自动缩分器是为地质、煤炭、建筑、冶金等系统的科研单位实验室,以及高等院校作试样自动分样的新型缩分装置。

FX3-8 is a new type of enclosed automatic sample splitting device for scientific research laboratories in geology, coal, construction and metallurgy systems and for institutions of higher learning.

二、结构及工作原理简介

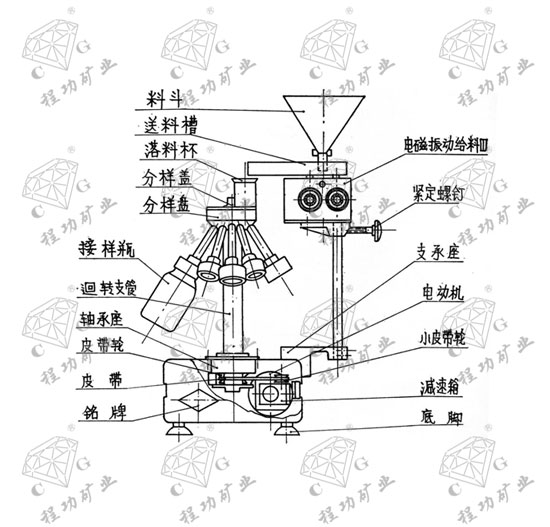

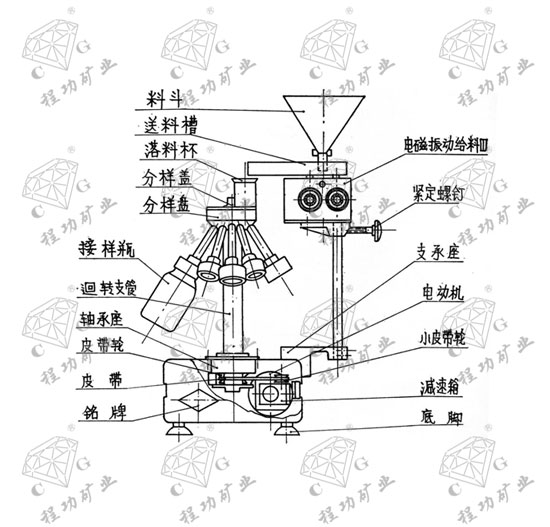

FX3-8封闭试样自动缩分器结构图

Configuration of FX3-8 enclosed auto sample splitting device

| 料斗 |

Hopper |

| 送料槽 |

Feed channel |

| 落料杯 |

Reception beaker |

| 分样盖 |

Splitting cover |

| 分样盘 |

Splitting tray |

| 电磁振动给料器 |

Electromagnetic vibratory feeder |

| 紧定螺钉 |

Set screw |

| 接样瓶 |

Sample collection bottle |

| 回转支管 |

Revolution tube |

| 轴承座 |

Bearing block |

| 皮带轮 |

Pulley |

| 皮带 |

Rubber belt |

| 铭牌 |

Nameplate |

| 支承座 |

Bearing bracket |

| 电动机 |

Motor |

| 小皮带轮 |

Small pulley |

| 减速箱 |

Reduction gearbox |

| 底脚 |

Footing |

该机由盛料斗、电磁振动给料器、分样装置,以及接样瓶五个部分组成。

盛料斗为一锥形结构,所分析的矿样可以一次性的倒入料斗中,起到储存矿样作用。

电磁振动给料器:分振动源和直料槽两部分,利用振动原理将盛料斗流下的矿样均匀地散步在直料槽中,不同的重要颗粒都能均匀地分布在不同的表层上,并逐步流向槽口而进入分样漏斗。该部分只有微小的振动,没有强烈的搅拌、撞击、摩擦等现象,结构简单,自动化程度高,且不需润滑,动力消耗小。

分样装置:是一种旋转结构,其箱内装有一台电动机,通过蜗杆蜗轮传动,达到减速,以一种固定的速度带动回转支管旋转,与回转支管相连接的分样盘(用紧定螺旋钉紧固)也同时转动。分样盘盘的八个等分锥孔先后截取从漏斗中流下的矿样,锥孔轴心和漏斗孔轴心相吻合,由于转动速度较快,在开始和停止截料时,各孔中的矿样重量误差很小,每一个锥孔下端都固定一个直管道,矿样就从管道进入接样瓶内。

接样瓶:接样瓶与固定在直管端部的接头相连接,并同时与回转支管一道转动,每个管子都连接一个样瓶,每次需上八个瓶子,每个瓶子里的矿样重量,即为缩分矿样总重量的八分之一,若将对角上的两个瓶子里的矿样合在一起,其重量即为总重量的四分之一,以此类推,两个四分之一的矿样合在一起,其重量即为总重量的二分之一。因此,每次缩分即可达到1~3级(1/8,1/4和1/2)缩分目的。

This device is composed of hopper, electromagnetic vibratory feeder, splitting device and collection bottle.

Hopper is a conical structure. All ore samples could be put into the hopper for storage.

Electromagnetic vibratory feeder is composed of vibration source and straight channel, distributing the ore sample from hopper evenly in the channel through vibration. In this way, different significant particles may be evenly distributed on different surfaces and move to channel opening gradually and then enter the splitting hopper. There is only micro vibration but no fierce stirring, impact and friction etc. occurs at this section which features simple structure, high degree of automation, no lubrication demand and low power consumption.

Splitting device is a rotating mechanism with a motor in the box which is designed to reduce the speed through worm and worm wheel and drive the revolution tube to rotate at fixed speed. The splitting tray (fixed through set screws) connected to revolution tube rotates at the same time. The eight division taper holes of splitting tray pick up the sample ore from the hopper in succession. The taper hole axis is aligned to hopper hole axis. Thanks to the high rotation speed, the weight error of sample ore in each hole is extremely small when the sample pick-up is started and stopped. At the lower part of each taper hole is a straight tube, through which the sample ore moves into sample collection bottle.

ample collection bottle is connected to the joint fixed at the end of straight tube and moves along with the revolution tube. Each short pipe is connected to a bottle. Eight bottles are connected at the same time, and each bottle collects sample ore of the same weight, i.e. 1/8 of total weight of sample being splitted. By mixing the sample ore in the two bottles on the same diagonal line, the weight will become 1/4 of total weight. Similarly, the weight of sample ore will reach 1/2 of the total weight by mixing the two samples that respectively account for 1/4 of total weight. Hence, the splitting grade is grade 1-3 (1/8, 1/4 and 1/2).

| 型号规格 Model |

单位 Unit |

FX3-8 |

| 缩分等级 Splitting grade |

|

1/2,1/4,1/8 |

| 缩分进料粒度 Feed size |

mm |

<6 |

| 每次最大缩分量 Maximum weight for splitting |

Kg |

4 |

| 缩分自动控制时间 Auto control duration |

min |

0~6 |

| 振动给料器Vibratory feeder |

功率 Power |

Kw |

40 |

| 电压 Voltage |

V |

220 |

| 频率 Frequency |

次/分 |

3000 |

| 分样装置电机规格Specification for motor of sampling splitting device |

功率 Power |

Kw |

15 |

| 电压 Voltage |

V |

220 |

| 转速 speed |

转/分 |

2700 |

接样瓶规格(玻璃)

Sample collection bottle size (glass) |

ml |

50,370,500 |

| 外形尺寸(长×宽×高) Overall dimensions |

cm |

433570 |

| 安装方式 Installation mode |

|

台式安放

Mounted on bench |

| 机重(净重)(Net) Weight |

kg |

41 |

|