|

YT型、YSP型中浅孔凿岩机 Medium-shallow

Hole Rock Drill

YG型、YQ型中深孔及深孔凿岩机 Medium-deep

Hole and Deep Hole Rock Drill

凿岩机械广泛应用于煤炭、冶金、铁道、水利、国防等岩巷掘进和石方工程,适用于中硬和坚硬岩石上钻凿炮孔。

The Rock Drilling Machine can

be widely used in tunneling and rock excavation for coal mine, metal mine,

railway building, irrigation contruction and national defence, can be used for

drilling holes on the hard rock and medium-hard rock.

一、使用范围

I. Application Scope

YT25型气腿式凿岩机是一种高效、节能的凿岩机械。它与FT160X型气腿配套,广泛用于煤炭、冶金、铁道、交通、水利、基建和国防等岩巷掘进和石方工程中钻凿水平和倾斜的炮眼。作为一极多用、本机还可以通过FT170HJ型专用气腿与环形钻架配套用于立井掘进机械化作业钻凿垂直炮眼。凿孔直径可达46毫米,深度5米以上。该机配置手持手把,还可以手持凿岩机使用。

YT25 air-leg rock drills are a

kind of high-efficiency and energy-saving rock drilling machinery. They are

used with FT160X air leg. Such drills are widely used to excavate the stonedrif

in coal, metallurgy, railway, transportation, water conservancy, capital

construction, national defense, etc and drill horizontal and oblique shot hole

in rock excavation. This machine can also be used in the drilling of vertical

shot holes of shaft sinking mechanized operations through FT170HJ special air

leg and ring drilling rig. The drilling diameter can reach 46mm and the drilling depth can reach

over 5m. This machine is

equipped with handheld handle or handheld rock drills.

二、技术参数

| YT、YSP型中浅孔凿岩机Rock drill |

| 型号规格 |

YT-24 |

YT-25W |

YTP26 |

YT-30 |

YSP-45 |

| 钎尾规格 |

mm |

22×108

25×108 |

22×108

25×108 |

22×108

25×108 |

22×108

25×108 |

22×108

25×108 |

| 活塞直径 |

mm |

70 |

70 |

95 |

70 |

95 |

| 活塞冲程 |

mm |

70 |

70 |

50 |

70 |

47 |

| 冲击功 |

kgf·m |

>6 |

>6 |

>6 |

>6 |

>7 |

| 扭距 |

kgf·m |

>130 |

>130 |

>130 |

>130 |

>180 |

| 冲击频率 |

次/min |

1800-2200 |

>1800 |

>1800 |

>1800 |

2800-2900 |

| 压气压力 |

kg/cm2 |

5 |

5-6 |

0.4-0.63Mpa |

5 |

5 |

| 压气耗量 |

m3/min |

<2.8 |

<2.8 |

<2.8 |

<22.9 |

<5 |

| 钎头直径 |

mm |

34-38 |

34-38 |

34-38 |

34-38 |

35-42 |

| 凿岩深度 |

m |

5 |

5 |

5 |

5 |

6 |

| 配气方式 |

有阀 |

无阀 |

无阀 |

无阀 |

无阀 |

| 重量 |

kg |

22-25 |

24.5 |

26.5 |

25.5 |

40-45 |

| YG、YQ型中深孔及深孔凿岩机Rock drill |

| 型号规格 |

YSP-45 |

YG-40 |

YG-90 |

YG-80 |

YQ-100 |

| 类型 |

伸缩式 |

导轨式 |

外回转 导轨式 |

导轨式 |

潜孔式 |

| 冲击功 |

kgf·m |

7 |

10.5 |

20 |

18 |

7.5 |

| 扭矩 |

kgf·m |

>180 |

380 |

>1100 |

1000 |

电动机功率3kw |

| 频率 |

次/min |

>2700 |

1600 |

>2000 |

1800 |

1900 |

| 耗风量 |

m3/min |

>5 |

8 |

11 |

8.5 |

3 |

| 钻孔方向 |

℃ |

上向 |

0-90 |

0-90 |

0-90 |

0-90 |

| 钻孔直径 |

mm |

45-75 |

45-75 |

45-75 |

45-75 |

95-110 |

| 钻孔平均深度 |

m |

6-8 |

15 |

15-20 |

13-15 |

15-20 |

| 机重 |

kg |

45 |

36 |

90 |

74 |

260 |

三、工作原理及操纵

Ⅲ. Working Principle and Control

YT25型凿岩机活塞的往复运动采用双气路无阀配气,它是利用活塞尾部的圆柱及凹槽在活塞运动中自动配气。

The reciprocating movement of

piston in YT25 roll drills adopts double gas circuit valueless gas

distribution. They automatically distribute air during piston motion through

the cylinder and groove at the end of the piston.

1、活塞的往复运动

1. Reciprocating Movement of Piston

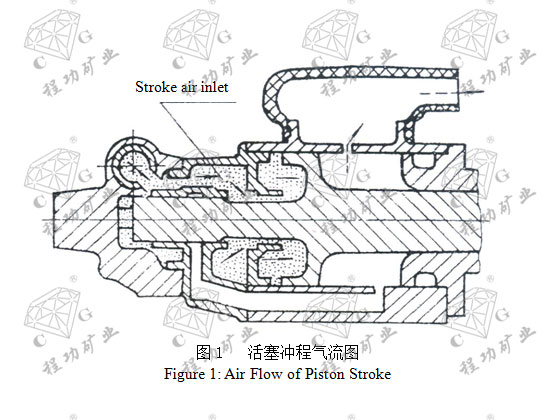

a、冲程:如图1。压缩空气从进气弯管进入操纵阀,通过气路进入气缸中活塞大圆左侧的空腔(简称左腔),推动活塞向右运动(往前)。

a. Stroke: As shown in Figure

1. The compressed air enters the operating valve from the intake bend. It

enters the cavity on the left of piston big circle (“left cavity” for short) in

the air cylinder through gas circuit to drive the piston to move to the right

(forward).

活塞尾部配气圆柱面经过阀体冲程进气口,到进气口被完全堵住时,便切断压缩空气向左腔的供气,此时,依靠左腔内的空气膨胀作功,推动活塞继续向右运动。当活塞大头左端面通过排气口时,左腔气体迅速排出,活塞依靠惯性继续向右运动,直至冲击钎尾端面。

The air distribution cylindrical

surface at the end of piston passes through the valve stroke air inlet and cuts

off supply of compressed air to the left cavity when it is completely blocked at

the air inlet. At this time, it does work through the expansion of air in the

left cavity and drives the piston to continue to move to the right. When the

left end face of the piston big end passes the air outlet, the air in the left

cavity is rapidly expelled. The piston continues to move to the right through

the force of inertia until it impacts the drill shaft end face.

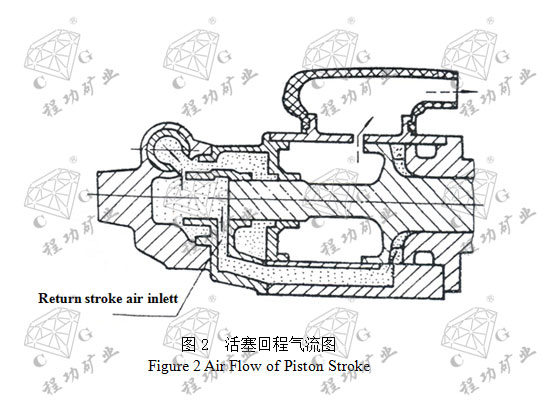

b、回程:如图2、活塞冲击钎尾回跳后,压缩空气从回程进气口通入活塞大头右侧空腔(简称右腔),推动活塞向左运动(往后)。

b. Return stroke: As shown in

Figure 2. After the piston impacts the drill shaft and rebounds, the compressed

air enters the cavity on the right of piston big end (“right cavity” for short)

from the return stroke air inlet

活塞尾部的配气圆柱面经过阀体回程进气口,到进气口被完全堵住时,便切断了压缩空气向右端的供气,活塞依靠右腔内的压缩空气膨胀作功,继续向左运动。当活塞大头右端面通过排气口时,右腔内的气体迅速排出,活塞则依靠惯性继续向左运动到回程的终点,活塞完成了一个往复循环。紧接着又开始下一个循环。

The air distribution cylindrical

surface at the end of piston passes through the valve return stroke air inlet

and cuts off supply of compressed air to the right cavity when it is completely

blocked at the air inlet. At this time, it does work through the expansion of

air in the right cavity and drives the piston to continue to move to the left.

When the right end face of the piston big end passes the air outlet, the air in

the right cavity is rapidly expelled. The piston continues to move to the left

through the force of inertia until it reaches the finishing point of the return

stroke. So far the piston has finished one recirculation. Then the next cycle

begins.

2、转钎运动:

2. Drilling

Motion

棘轮与螺旋母靠螺纹连成一体,螺旋母套在活塞螺旋齿上。活塞冲程时,棘轮可相对活塞转动一个角度,活塞只作直线运动。活塞回程时,因棘轮被回转爪顶住不能转动,追使活塞沿螺旋槽转动一个角度,同时,活塞直齿带动花键母(与转动套连成一体)亦相应转动一个角度,转动套的六方孔也带动钎杆 一同转动,从而实现转钎动作。

The ratchet wheel and nuts are linked

through screw threads. The nuts are covered on the piston spiral tooth. During

the stroke of piston, the ratchet wheel can rotate for an angle relative to the

piston. The piston only makes linear motion. During the return stroke of

piston, as the ratchet wheel is propped up by the catch hook and is not able to

turn, the piston has to turn for an angle along the spiral groove. At the same

time, the straight teeth drive the spline (integrated with rotating sleeve) to

turn for an angle. The Allen hole of rotating sleeve also drives the drill rod

to turn, so as to realize drilling.

3、气腿推力的调节及快速收缩

3. Adjustment of

Air Leg Thrust and Rapid Contraction of Air Leg

a、气腿推力的调节

a. Adjustment of Air Leg Thrust

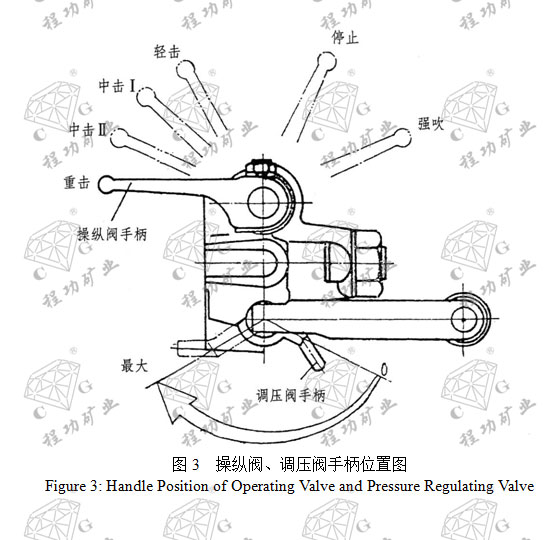

气腿推力的大小靠调节调压阀手柄的位置。如图3.调压阀手柄从零位调向最大,可获得由零到最大的推力。凿孔时,凿岩机是依靠气腿的推力来推进的,适当地调节调压阀以获得最佳推力及最快的凿岩速度。

The air leg thrust can be

adjusted by adjusting the position of handle of pressure regulating valve as

shown in Figure 3. The handle of pressure regulating valve is adjusted to the

maximum from the zero position and thrust from zero to the maximum can be

acquired. During drilling, the rock drills are pushed through the thrust of air

leg. Proper adjustment is made of the pressure regulating valve to get the best

thrust and the fastest drilling speed.

b、气腿的快速收缩

b. Rapid Contraction of Air Leg

抓住主机手把上的尼龙板机就可压下换向阀的杆部,气腿活塞杆即快速收回。此时,可不必关闭操纵阀和调压阀。

Grasp the nylon board on the

handle of the mainframe and the rod of change valve can be pressed down. The

air leg piston rod can rapidly contract. At this time, the operating valve and

pressure regulating valve do not need to be shut off.

4、机器的运转

4. Operation of

Machine

机器运转有六个工作内容,靠操纵阀手柄来控制。手柄有六个位置,如图3.每个位置的工作内容见表2.

There are six parts for the

operation of machine. The machine is controlled through the handle of operating

valve. There are six positions in the handle as is shown in Figure 3. See Table

2 for the working contents for every position.

| 工作位置 |

活塞运动 |

气针吹气 |

水针给水 |

气腿伸缩 |

| 强 吹 |

停 止 |

停 止 |

停 止 |

可以伸缩 |

| 停 止 |

| 轻 击 |

运 动 |

吹 气 |

给 水 |

| 中 击 Ⅰ |

| 中 击 Ⅱ |

| 重 击 |

轻击:Gentle

strike

中击I:Medium

strike I

中击II:Medium

strike II

重击:Violent

strike

操纵阀手柄:Handle

of operating valve

最大:Maximum

调压阀手柄:Handle

of pressure regulating valve

强吹:Strong

blow

停止:Stop

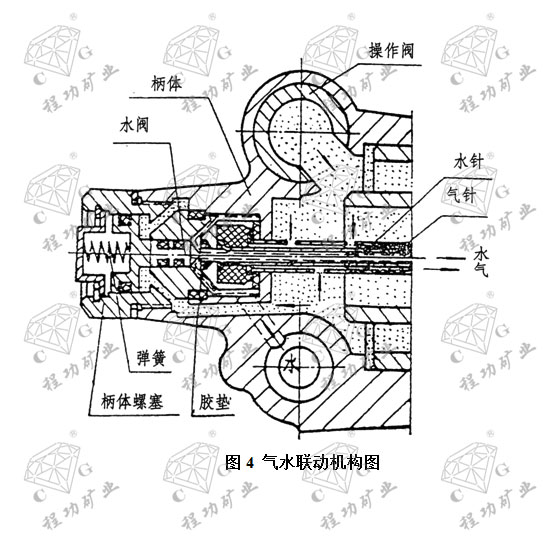

5、气水联动机构

5. Air Water Link Mechanism

该机构设在柄体上,如图4、凿岩机开动时即供水。供水、断水的过程是通过扳动操作阀手柄来实现的。当操纵阀手柄扳到轻击位置时(包括以后的中击,重击位置在内),操纵阀向气缸充气的气路开始打开,压缩空气由操纵阀进气口经柄体空腔通入气缸,充满柄体空腔的压缩空气经过气路推动水阀向左移动打开水路,水即经有关水路通入水针,并进入钎杆中心孔到炮眼底部冲洗岩粉。当扳动操纵阀手柄到停止位置时,向气缸供气的通路被操纵阀切断,凿岩机停止工作,同时,由于柄体空腔内余气排空,水阀在弹簧作用下向右移动,堵住胶垫中心孔,将水路关闭。

This mechanism is installed on

the handle as shown in Figure 4. Water is supplied when the rock drill is

started. The processes of water supply and its cut off are realized through the

pulling of the operating valve’s handle. When the handle of the operating valve

is pulled to the position of “gentle strike” (including the subsequent “medium

strike” and “heavy strike”), the gas circuit of operating valve’s gas filling

to the air cylinder begins to be opened. The compressed air flows flow the air

inlet of operating valve, through the handle cavity, and to the air cylinder.

The compressed air filling the handle cavity drives the water valve to open the

water way to the left through the gas circuit. Then the water flows to the

squirt through relevant water ways and enters the center hole of drill rod to

the bottom of shot hole to wash rock powder. When the handle of operating valve

is pulled to the “stop” position, the passage through which air is supplied to

the air cylinder is cut off by the operating valve. The rock drills stop. At

the same time, as the residual air in the handle cavity is empties, the water

valve moves to the right under the action of spring, blocks the center hole of

rubber mat, and shuts off the water way.

6、气针的排水作用

6. Water Discharge of Gas Needle

在水针外套一根气针,如图4。两管之间有一环形空间,凿岩机工作时,有压缩空气通过,有助于使水针的水更好地进入钎杆中孔,同时,可以防止水倒流入凿岩机内部,以保证建立较好的润滑条件。

Cover

one gas needle outside the water needle as is shown in Figure 4. There is one

section of annular space between the two pipes. During the operation of rock

drills, compressed air passes by, which helps the water in the water needle

better enter the center hole of drill rod. Besides, it can prevent water from

flowing back to the inside of the rock drill, so as to ensure good lubricating

conditions.

|