|

|

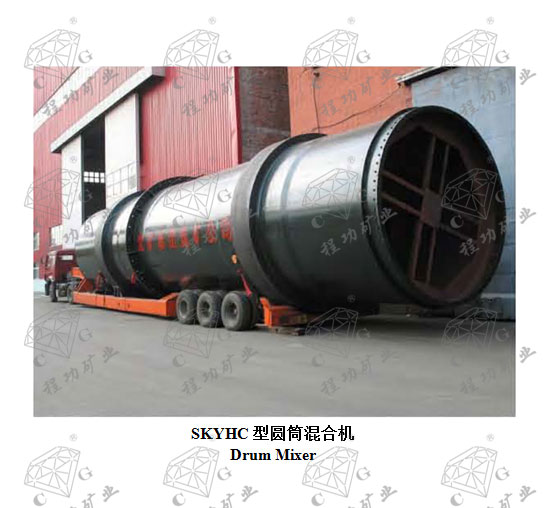

SKYHC型圆筒混合机 Drum

Mixer

1、用途:圆筒混合机是烧结、球团系统中重要设备之一,可用于原料混合、制粒、滚煤等多种用途,满足烧结机对原料的要求。

1. Application: Drum mixers are one of the important types of

equipment in the sintering and pelleting system. They can be used for many

purposes such as raw material blending, pelletization, and coal coating to meet

the requirements of sintering machines for raw materials.

2、结构及特点:圆筒混合机的传动结构主要有齿轮传动及胶轮传动两种。齿轮圈传动具有传动扭矩大、寿命长等特点,但噪音较大;胶轮传动可用实心或空心充气轮胎,具有传动平稳、噪音低等特点,但胶轮磨损较大,更换资数多。胶轮传动的传动装置根据用户要求可置于中间或两端,所有设备都有左右传动安装形式。

2. Structure and Characteristic: The transmission structures of

drum mixers are mainly divided into two types, gear transmission structure and

rubber tire transmission structure. Gear transmission structure has the

characteristics of large driving torque, long service life, but loud produced

noise. Rubber tire transmission structure can use solid or hollow pneumatic tire

which has the characteristics of smooth transmission, low noise, but large rubber

tire abrasion and many times of replacement. The transmission mechanism can be

placed in the middle or at two ends according to the requirements of user. All

equipment has the installation form of left and right transmission.

(一) 用途:圆筒混合机是烧结、球团系统中重要设备之一,可用于原料混合、制粒、滚煤等多种用途,满足烧结机对原料的要求。

(I) Application: Drum mixers are one of the important types of

equipment in the sintering and pelleting system. They can be used for many

purposes such as raw material blending, pelletization, and coal coating to meet

the requirements of sintering machines for raw materials.

(二) 结构及特点:圆筒混合机的传运结构主要有齿轮传动及胶轮传动两种。齿轮齿圈传动具有传动扭矩大、寿命长等特点,但噪音较大;胶轮传动可用实心或空心充气轮胎,具有传动平稳、噪音低等特点,但胶轮磨损较大,更换次数多。胶轮传动的传动装置根据用户要求可置于中间或两端,所有设备都有左右传动安装形式。

(II) Structure and Characteristic: The transmission structures of

drum mixers are mainly divided into two types, gear transmission structure and

rubber tire transmission structure. Gear transmission structure has the

characteristics of large driving torque, long service life, but loud produced

noise. Rubber tire transmission structure can use solid or hollow pneumatic tire

which has the characteristics of smooth transmission, low noise, but large

rubber tire abrasion and many times of replacement. The transmission mechanism

can be placed in the middle or at two ends according to the requirements of

user. All equipment has the installation form of left and right transmission.

为了提高混料效果,筒体内装有扬料板;为了防止粘料,筒体内还装有整体或部分衬板。衬板有金属、耐磨橡胶、含油尼龙、高分子材料等多种形式供用户选择。

To improve the effects of material mixing, the drum is equipped

with raising material board. To prevent sticking of materials, the drum is also

equipped with entire or partial lining plates. The lining plates can be made of

metal, wear-resisting rubber, oil-bearing nylon, high molecular material, etc

for users’ choices.

(三)圆筒机的倾角:应根据混合时间及混合机的作用确定。一般情况下一混不大于3º,二混约为1.5º.

(III) Inclination Angle of Drum Mixer: The inclination angle shall

be determined according to mixing time and functions of mixer. Normally, it

shall not be larger than 3º during the first mixture and shall be 1.5º during

the second mixture.

(四)混合时间:根据实践经验混合时间一般可定为不少于5分钟,其中一混约定俗成分钟,二混约3分钟。混合时间与原料的各类,成球性有很大关系。

(IV) Mixing Time: According to practical experience, the mixing

time can normally be fixed to be not shorter than 5 minutes. The time shall be

fixed during the first mixture and shall be 3 minutes during the second

mixture. The time of mixing largely depends on the type of raw material and

balling.

(五)圆混机的填充率:一混为10~20%,二混为10~15%左右。

(V) Fill Ratio of Drum Mixer: 10~20% during the first mixture and

around 10~15% during the second mixture.

(六)我厂生产过的最大圆混机Φ3.8×15m、Φ3×12m(胶轮)。

(VI) The largest drum mixer manufactured by our factory is Φ3.8×15m and Φ3×12m in rubber tire.

(七)主要圆混合机的技术参数如下:

(VII) The main technical parameters of drum mixers are as follows:

技术参数Ⅰ

| 型号规格 |

SKYHC 3090 |

SKYHC 30120 |

SKYHC 30120 |

SKYHC 30120 |

SKYHC 30120 |

SKYHC 32120 |

| 圆筒直径 |

mm |

3000 |

3000 |

3000 |

3000 |

3000 |

3200 |

| 圆筒长度 |

mm |

9000 |

12000 |

12000 |

12000 |

12000 |

12000 |

| 筒体转速 |

r/min |

7 |

6.144 |

7.5 |

6.787 |

7 |

6.5 |

| 筒体倾角 |

(0) |

4 |

2.5 |

1.5 |

0.75 |

2.5 |

2.29 |

| 处理量 |

t/h |

340-430 |

400 |

380-420 |

142 |

325-410 |

500-600 |

| 物料堆比重 |

t/m3 |

1.7 |

1.8 |

1.7 |

1.6 |

1.7 |

1.7 |

| 填充率 |

% |

6.88-8.7 |

17.254 |

101 |

13 |

12.25 |

16.43 |

| 电机功率 |

kw |

132 |

200 |

132 |

280 |

220 |

400 |

| 重量 |

t |

73 |

157 |

100 |

105 |

79 |

97 |

| 配烧结机 |

m2 |

132 |

132 |

198 |

132 |

2×132 |

2×90 |

技术参数Ⅱ

| 型号规格 |

SKYHC 32120 |

SKYHC 32120 |

SKYHC 32120 |

SKYHC 32120 |

SKYHC 32130 |

SKYHC 32160 |

| 圆筒直径 |

mm |

3200 |

3200 |

3200 |

3200 |

3200 |

3200 |

| 圆筒长度 |

mm |

12000 |

12000 |

12000 |

12000 |

12000 |

12000 |

| 筒体转速 |

r/min |

6.5 |

7 |

7 |

7 |

7 |

6 |

| 筒体倾角 |

(0) |

2 |

2 |

2.2 |

2.5 |

2.5 |

1.3 |

| 处理量 |

t/h |

440-560 |

240-390 |

504-580 |

325-410 |

612-734 |

250-300 |

| 物料堆比重 |

t/m3 |

1.7 |

1.7 |

1.7 |

1.7 |

1.7 |

1.7 |

| 填充率 |

% |

14.8 |

13.02-14.94 |

15.44 |

12.25 |

15.34-18.4 |

9.03 |

| 电机功率 |

kw |

250 |

220 |

250 |

220 |

400 |

400 |

| 重量 |

t |

137.5 |

98 |

126 |

79 |

162.2 |

127 |

| 配烧结机 |

m2 |

198 |

2×30 |

198 |

2×132 |

240 |

2×90 |

技术参数Ⅲ

| 型号规格 |

SKYHC 33140 |

SKYHC 35140 |

SKYHC 35140 |

SKYHC 3680 |

SKYHC 36130 |

SKYHC 36140 |

| 圆筒直径 |

mm |

3300 |

3500 |

3500 |

3600 |

3600 |

3600 |

| 圆筒长度 |

mm |

14000 |

14000 |

14000 |

8000 |

13000 |

14000 |

| 筒体转速 |

r/min |

7 |

6.4 |

7 |

6.78 |

7 |

6.5 |

| 筒体倾角 |

(0) |

2.5 |

1.5 |

1.8 |

2.5 |

2 |

2.5 |

| 处理量 |

t/h |

436-502 |

340-390 |

520-600 |

842-1010 |

730-930 |

780-900 |

| 物料堆比重 |

t/m3 |

1.9 |

1.7 |

1.8 |

1.6 |

1.7 |

1.9 |

| 填充率 |

% |

12.34 |

11.77-13.5 |

12.94 |

16.1-19.3 |

7.9-19.9 |

13.1 |

| 电机功率 |

kw |

400 |

400 |

400 |

280 |

450 |

500 |

| 重量 |

t |

142 |

125 |

158 |

97 |

215 |

173 |

| 配烧结机 |

m2 |

2×40 |

2×30 |

180 |

360 |

132 |

2×40 |

技术参数Ⅳ

| 型号规格 |

SKYHC 36140 |

SKYHC 36160 |

SKYHC 36160 |

SKYHC 3895 |

SKYHC 38140 |

SKYHC 38140 |

| 圆筒直径 |

mm |

3,600 |

3,600 |

3,600 |

3,800 |

3,800 |

3,800 |

| 圆筒长度 |

mm |

14,000 |

16,000 |

16,000 |

9,500 |

14,000 |

14,000 |

| 筒体转速 |

r/min |

6.6 |

7.5 |

7.5 |

6.5 |

6.5 |

6.5 |

| 筒体倾角 |

(0) |

2.5 |

2.3 |

2 |

2.6 |

2.5 |

2.5 |

| 处理量 |

t/h |

820-1000 |

350-400 |

380-420 |

1128-1357 |

842-1010 |

765-895 |

| 物料堆比重 |

t/m3 |

1.8 |

1.7 |

18 |

1.7 |

1.7 |

1.7 |

| 填充率 |

% |

14.52 |

13.42 |

7.29-8.06 |

17.2-20.7 |

14.2-17.05 |

12.13 |

| 电机功率 |

kw |

500 |

500 |

355 |

315 |

500 |

500 |

| 重量 |

t |

173 |

198 |

183.59 |

172 |

196 |

196 |

| 配烧结机 |

m2 |

180 |

170 |

198 |

450 |

360 |

238 |

技术参数Ⅴ

| 型号规格 |

|

SKYHC 38140 |

SKYHC 38170 |

SKYHC 38170 |

SKYHC 38170 |

SKYHC 4080 |

SKYHC 40180 |

| 圆筒直径 |

mm |

3,800 |

3,800 |

3,800 |

3,800 |

4,000 |

4,000 |

| 圆筒长度 |

mm |

14,000 |

17,000 |

17,000 |

17,000 |

8,040 |

18,000 |

| 筒体转速 |

r/min |

6.5 |

5.5-7.5 |

6.5 |

5.5-7.5 |

8.6 |

8.5 |

| 筒体倾角 |

(0) |

2.7 |

1.5 |

1.5 |

3 |

1.1 |

1.1 |

| 处理量 |

t/h |

940-1080 |

460-510 |

510-580 |

440-516 |

|

325-410 |

| 物料堆比重 |

t/m3 |

1.7 |

1.7 |

1.7 |

1.7 |

1.1-1.3 |

1.7 |

| 填充率 |

% |

13.85 |

10.71-14.58 |

12.66 |

10.09-13.76 |

|

10.05 |

| 电机功率 |

kw |

500 |

630 |

560 |

355 |

710 |

710 |

| 重量 |

t |

196.5 |

194.7 |

194.7 |

219 |

100.4 |

278 |

| 配烧结机 |

m2 |

360 |

198 |

198 |

198 |

|

2×132 |

技术参数Ⅵ

| 型号规格 |

SKYHC 40180 |

SKYHC 44170 |

SKYHC 44200 |

SKYHC 50130 |

SKYHC 51245 |

| 圆筒直径 |

mm |

4,000 |

4,400 |

4,400 |

5,000 |

5,100 |

| 圆筒长度 |

mm |

18,000 |

17,000 |

20,000 |

13,000 |

24,500 |

| 筒体转速 |

r/min |

8.5 |

6.5 |

6 |

2-5 |

5.6 |

| 筒体倾角 |

(0) |

1.1 |

1.2 |

2.2 |

7 |

2.5 |

| 处理量 |

t/h |

325-410 |

612-734 |

950-1093 |

708 |

1150 |

| 物料堆比重 |

t/m3 |

1.7 |

1.7 |

1.7 |

2.2-2.3 |

2 |

| 填充率 |

% |

10.05 |

15.53 |

11.82-13.59 |

|

9.12 |

| 电机功率 |

kw |

710 |

800 |

900 |

250 |

1,000 |

| 重量 |

t |

278 |

297.5 |

294.7 |

|

|

| 配烧结机 |

m2 |

2×132 |

240 |

360 |

500 |

360 |

技术参数Ⅶ

| 型号规格 |

SKYHJ 2568 |

SKYHJ 2890 |

SKYHJ 28100 |

SKYHJ 3090 |

SKYHJ 32120 |

SKYHJ 32140 |

| 圆筒直径 |

mm |

2,500 |

2,800 |

2,800 |

3,000 |

3,200 |

3,200 |

| 圆筒长度 |

mm |

6,800 |

9,000 |

10,000 |

9,000 |

12,000 |

14,000 |

| 筒体转速 |

r/min |

7 |

6 |

7 |

7.5 |

6.5-9 |

7 |

| 筒体倾角 |

(0) |

2.5 |

2 |

3 |

1.5 |

0.75 |

1.6 |

| 处理量 |

t/h |

200 |

292-336 |

400 |

190-220 |

142-180 |

295-340 |

| 物料堆比重 |

t/m3 |

1.7 |

1.7 |

1.7 |

1.7 |

1.8 |

1.7 |

| 填充率 |

% |

|

16.1 |

12.65 |

9.6 |

13 |

11.48 |

| 电机功率 |

kw |

75 |

132 |

160 |

160 |

185 |

220 |

| 重量 |

t |

47 |

62 |

67 |

70 |

102 |

110 |

| 配烧结机 |

m2 |

180 |

180 |

75 |

198 |

360 |

180 |

| |