|

CGYS 圆筒隔渣筛Rotary Screen

一、概述

CGYS系列圆筒隔渣筛适用于浓度小于50%的矿浆中粗颗粒及草屑等杂质的筛分,是为CGYS磁选机配套设计的隔渣装置,可有效防止磁选机磁介质堵塞。本圆筒筛也适用于煤炭、冶炼、建材、化工等其它行业需要除渣的地方。

本系列圆筒隔渣筛具有处理量大,占地小,对给矿粒度、浓度的波动适应性强,运动部件磨损小、故障率低,工作可靠、操作维护简便等优点。

二、设备构造

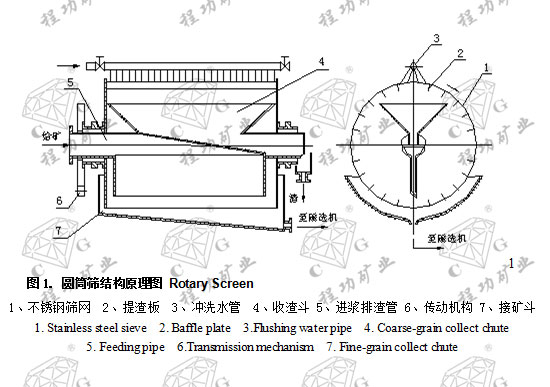

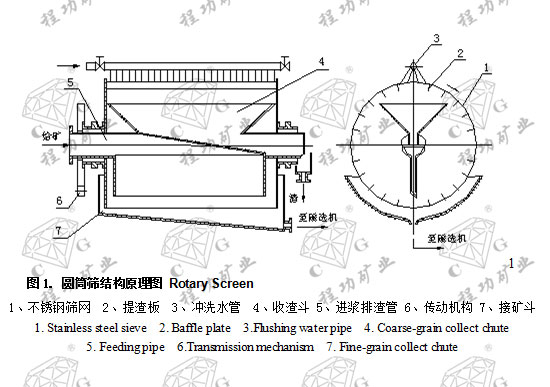

CGYS系列圆筒筛的结构如图1所示,它主要由不锈钢筛网、提渣板、冲洗水管、收渣斗、进浆排渣管、传动机构和接矿斗组成。

1. Introduction

CGYS rotary screens are suitable for

screening out coarse particles from slurry, which feed density (solids) is less

than 50%. It was designed as support equipment for CGYS Magnetic Separator to

remove coarse grains and it is quite efficient for preventing the matrix of CGYS

machine from clog. This screen can also be used in many other industries such

as coal industry, smelting industry, building industry and chemical industry

where need removing coarse-grained material.

This range of rotary screens has the

advantages of large capacity, taking up small space, adaptability for

fluctuation of feeding grain size and feed density (solids), reliable working

and easy operation and maintenance.

2.

Structure

The structure of CGYS Rotary Screen consists

chiefly of stainless steel sieve, baffle plates, flushing water pipe,

coarse-grain collect chute, feeding pipe, transmission mechanism and fine-grain

collect chute as shown in Fig.1

三、工作原理

工作时,装配筛网的圆筒在传动机构的驱动下旋转,矿浆从进浆排渣管的左下部给入到筛网的圆周上。细粒矿物和水穿过筛网落入到接矿斗,沿管道自流至下一道工艺。粗粒部分被提渣板提至顶部被冲洗水冲入收渣斗排走。

3.

Principle of Operation

The cylinder with sieve

that is driven by the transmission mechanism rotates when the machine is in

operation.

Ore

pulp is fed onto the cylinder sieve through feeding pipe. The fine grains and

water pass through the sieve and are collected by fine-grain collect chute for

next process stage. At the same time the coarse grains deposit on the sieve and

are lifted to the top by baffle plates in the cylinder and then be flushed down

into the coarse-grain collect chute by water

四、规格型号和主要参数

| 型号规格Model |

单位Uite |

CGYS-Φ800×1000 |

CGYS-Φ1200×1000 |

CGYS-Φ1420×1500 |

CGYS-Φ2000×1950 |

CGYS-Φ2500×2950 |

| 圆筒直径×长度 Diameter

× Length |

mm |

Φ800×1000 |

Φ1200×1000 |

Φ1420×1500 |

Φ2000×1950 |

Φ2500×2950 |

| 除渣粒度×Sieve size |

mm |

0.5~5.0 |

0.5~5.0 |

0.5~5.0 |

0.5~5.0 |

0.5~5.0 |

给矿浓度

Feeding density |

% |

≤50 |

≤50 |

≤50 |

≤50 |

≤50 |

| 处理能力Capacity |

t/h |

10~15 |

30~45 |

50~80 |

100~150 |

150~280 |

最大给矿体积

Maximum

feed volume |

m3/h |

50 |

100 |

200 |

400 |

750 |

传动功率

Drive

power |

kw |

1.5 |

1.5 |

2.2 |

4.0 |

7.5 |

| 耗水量Water consumption |

m3/h |

1~2 |

3~5 |

5~10 |

10~20 |

18~35 |

| 外形尺寸(长×宽×高)Overall dimensions |

mm |

2400×1300

×1500 |

2980×1440

×1730 |

4000×1600

×2500 |

4750×2140

×2780 |

6300×2900

×3600 |

| 机重Weight |

t |

1.0 |

2.2 |

3.5 |

6.8 |

14.5 |

| 根据给矿浓度、粒度及所处流程位置,可配CGYS磁选机型号 |

CGYS-750

CGYS-1000

CGYS-1250 |

CGYS-1250

CGYS-1500 |

CGYS-1500

CGYS-1750

CGYS-2000 |

CGYS-2000

CGYS-2500 |

CGYS-2500

CGYS-3000 |

×除渣粒度根据实际筛分要求确定

|