|

|

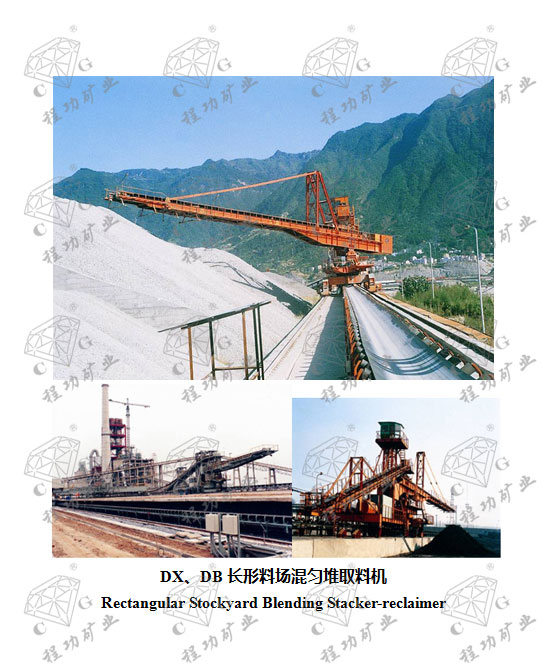

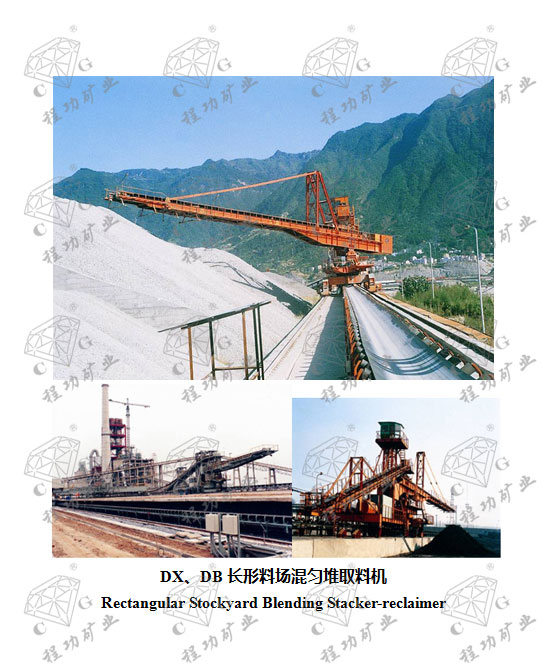

DX、DB型长形料场混匀堆取料机 Rectangular

Stockyard Blending Stacker-reclaimer

长形料场混匀堆取料机适用于长形料场。主要用来对水泥石灰石原料和其他辅助原料的预均化。也广泛用于煤炭、电力、港口等行业,是散状物料均化处理设备。

Rectangular stockyard blending

stacker-reclaimers apply to rectangular stockyard which are mainly used to

preblend cement and limestone raw materials and other auxiliary raw materials.

They are widely used in coal, power, port and other industries and are blending

equipment for bulk materials.

长形料场混匀堆取料机其堆料机型式主要有侧式悬臂堆料机、侧式悬臂回转堆料机、顶部卸料小车式堆料机等。取料机有桥式刮板取料机、侧式刮板取料机、侧式刮斗取料机、门架式刮板取料机、桥式斗轮取料机等。可满足日产1000t、2000t、4000t、5000t、10000t水泥厂石灰石料场和辅助圆料场的生产需要,也可满足其他散状物料的堆取料作业。可应用于室内、室外等多种环境。

Maimly include side- cantilever stacker,

side-cantilever gyration stacker, and top discharge trolley stacker. The types

of reclaimers include bridge-type scrapper reclaimer, side-type scrapper

reclaimer, side-type scraping bucket reclaimer, portal-type scraper reclaimer,

bridge-type bucket wheel reclaimer, etc. Such reclaimers can meet the

requirement of manufacturing 1,000t, 2,000t, 4,000t, 5,000t, 10,000t limestone

stockyards of cement plant and auxiliary circular stockyards each day, as well

as meet the requirement of stacking and reclaiming other bulk materials. They

can be applied in various kinds of environment indoors and outdoors.

侧式悬臂回转堆料机

| 物料特性 |

名称 |

煤,矿石等 |

供电方式 |

安全滑触线, 电缆卷筒 |

| 堆积密度t/m3 |

0.62~2.5 t/m3 |

| 粒度(mm) |

0~300 |

| 含水量 |

-10% |

| 安息角° |

27°~50° |

通讯方式 |

电缆卷筒,滑触线,无线通讯 |

| 主要指标 |

堆料(t/h) |

600-6000 |

| 回转半径(m) |

20-56 |

侧式悬臂堆料机技术参数表

| 型号 |

DX110 -600 |

DX600 -1300 |

DB100 -600/17 |

DB800 /16.5 |

(H)DB 1000/15 |

(H)DB 1500/30 |

DB1800 /33.5 |

(H)DB 2000/22 |

(H)DB 2400/30 |

(H)DB 3000/35 |

(H)DB 3500/37 |

(H)DB 4000/40 |

| 名称 |

顶部卸料小车 式堆料机 |

侧式悬臂(回转)堆料机 |

| 生产能力(t/h) |

110- 600 |

600- 1300 |

100- 600 |

800 |

1000 |

1500 |

1800 |

2000 |

2400 |

3000 |

3500 |

4000 |

| 适用物料 |

煤、石灰石、铁、页岩、铝矾土、粘土及其它散状物料 |

| 行走轨距(m) |

2.65 |

4 |

4.5 |

5 |

4 |

5 |

6 |

8 |

| 带式输送机带宽(mm) |

500、650、800、1000、1200、1400、1600、1800、2000、2200、2400 |

| 带式输送机带速(m/s) |

0.8-3.15 |

| 堆料机臂长(m) |

― |

― |

17 |

16.5 |

15 |

30 |

33.5 |

22 |

24 |

23 |

24 |

35 |

| 俯仰角度 |

― |

― |

+17º -17º |

+11º -12º |

+15º -10º |

±14.5º |

+16º -13º |

+16º -10º |

+18º -11º |

+18º -12º |

+16º -13º |

+16º -11º |

| 变幅驱动方式 |

― |

― |

液压 |

| 控制方式 |

计算机自动控制;手动控制 |

| |