|

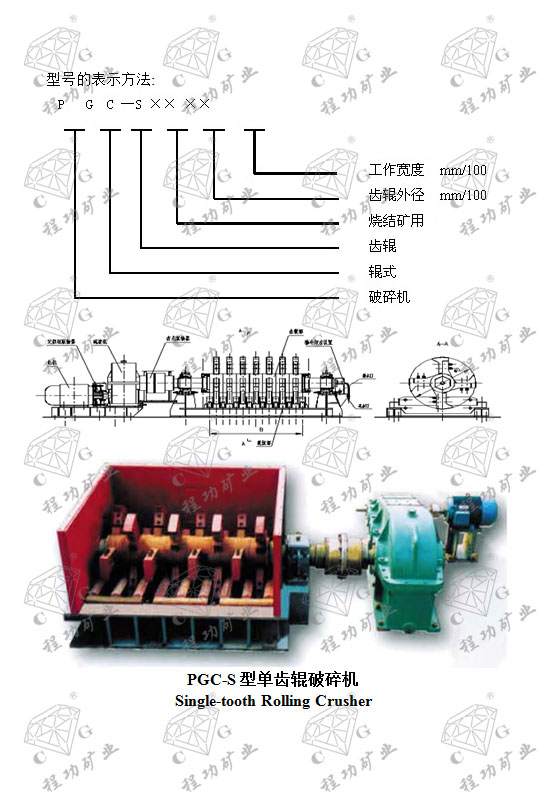

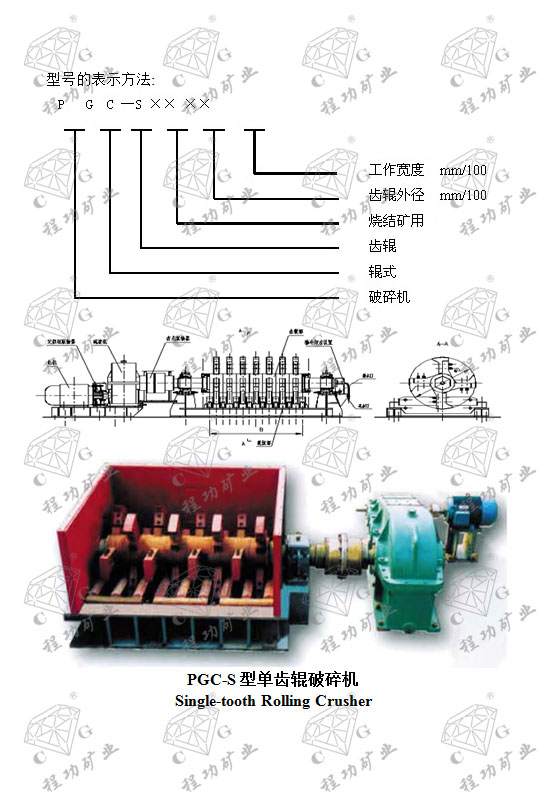

PGC-S型单齿辊破碎机 Single-tooth

Rolling Crusher

单齿辊破碎机安装在烧结机尾部,用来破碎经烧结后从烧结台车上卸下来的热烧结矿,是烧结厂整粒系统的主要设备。

Single-tooth rolling crushers

are installed at the end of the sintering machine to crush the hot sintered ore

unloaded from the sintering maching trolley after sintered. They are the main

equipment of size stabilization system in the ore-sintering plants.

我公司生产的单齿辊破碎机分别与烧结台车宽度为1.5米、2.5米、3.5米和5米的几种规格烧结机相配套。1980年后,引进了日本的先进技术,经几代技术人员的努力,在单齿辊破碎机的设计和制造工艺上不断改进,先已达到国际先进水平。经多年的运转实践证明:机器运转可靠,使用寿命长。近几年,工业自动化的发展迅速,我公司生产的单齿辊破碎机完全可适应烧结厂集中控制的工业程度。

The single roll crushers

produced by our company respectively match sintering machines of several specifications

with the widths of sintering maching trolley of 1.5m, 2.5m,

3.5m and 5m. In 1980, we introduced Japan ’s

advanced technology. After the effort made by several generations of

technicians, we continuously improve the design and manufacturing techniques of

single roll crushers. Now, they have reached the international advanced level.

Many years of operation practice demonstrate that the machines operate reliably

and enjoy long service life. In recent years, thanks to the rapid development

of industrial automation, the single roll crushers manufactured by our company

are able to adapt to industrial degree of sintering plants centralized control.

单齿辊破碎机由传动装置、齿辊(轴辊)装置、辊轴给排水冷却装置、支撑台车、篦板、密封罩、导槽等主要部分组成。由电动机通过安全联轴器,经减速装置带动齿辊旋转。篦板安装在齿辊下方,当热烧结矿从烧结机尾部卸下,通过导槽进入到篦板上面时,齿辊旋转借助破碎齿的剪切和挤压作用,将热烧结矿破碎成所需要的粒度。因破碎物料温度高,辊轴、辊齿、篦板均设计成通水冷却式,并在表面堆焊耐磨耐热的硬质合金,以提高使用寿命。破碎后的热烧结矿块从破碎机下溜槽进入冷却机。小型单齿辊破碎机只有主轴通水冷却,齿冠采用合金钢铸造,篦板上装有护板可以更换。

Single roll crushers are mainly

composed of transmission device, tooth roll (axle roll) device, roll shaft water

supply and drainage cooling device, supporting trolley, grate plate, seal

cover, and guide slot. The motor drives the rotation of roll through reducing

device by virtue of safety coupling. The grate plate is installed below the

roll. When the hot sintered ores are unloaded from the end of the sintering

machine and get to the top of the grate plate through the guide slot, the

rotating roll crushes the hot sintered ores into the required particle sizes

through the shearing and squeezing action of the crushing teeth. Since the

temperature of the crushing materials is high, the roll shaft, roll teeth and

grate plate are all designed into connecting water cooling type. Repair welding

of wear-resisting and heat-resisting is conducted on their surface to prolong their

service life. The crushed hot sintered ores enter the cooling machine from the

chute below the crusher. In the small single roll crusher, only the main shaft

uses water to cool. The crown is cast through alloy steel. The grate plate is

equipped with guard board which can be replaced.

为检修方便,齿辊本身也可以整体吊装。大规格单齿辊破碎机的篦板安放在可以移动的台车上,可整体拉出推入,以减少停车维修时间。

For the convenience of

examination and repair, the roll itself can be hoisted integrally. The grate

plate of large single roll crusher is placed in the movable trolley and can be

pulled out or pushed in integrally to reduce stopping and maintenance time.

单齿辊破碎机的安全联轴器、低速联轴器和大小齿轮等旋转运动部件必须有安全防护罩等装置,安全卫生。单齿辊破碎机自带防尘罩。大规格的破碎机带大型防尘罩,并能与吸尘装置相联接,卫生环保。吸尘装置可由用户自备。

Rotating parts such as safety

coupling, low-speed coupling, as well as big and small gears in the single roll

crusher must be equipped with devices such as safety shields. They are safe and

hygienic. The single roll crusher has dust cover of its own. Large crushers are

equipped with large dust covers and can connect with dust suction installations

which are safe and environmentally friendly. The dust suction installations can

be provided by the users themselves.

破碎机的型式如图所示, 该图不确定破碎机的具体结构。

The pattern of crusher is as

shown in the following figure. This figure does not indicate the specific

structure of the crusher.

主要技术性能参数

| 名称 |

单位 |

型号 PGC-S |

| 1118 |

1524 |

1628 |

1832 |

2037 |

2443 |

2451 |

| 处理能力 |

t/h |

140 |

180 |

460 |

520 |

565 |

750 |

1150 |

| 破碎后粒度≤ |

mm |

150 |

| 烧结矿温度 |

℃ |

750~850 |

| 齿辊转数 |

r/min |

6~8 |

| 齿辊外径 |

mm |

1100 |

1500 |

1600 |

1800 |

2000 |

2400 |

2400 |

| 工作宽度 |

mm |

1860 |

2400 |

2560 |

3230 |

3740 |

4340 |

5130 |

| 每排齿辊齿数 |

个 |

3 |

4 |

4 |

3 |

3 |

3 |

3 |

| 辊齿轴向排数 |

排 |

6 |

7 |

7 |

11 |

12 |

14 |

16 |

| 电机功率 |

kW |

22 |

55 |

75 |

110 |

110 |

150 |

150 |

| 机器外形尺寸 |

长≤ |

mm |

6300 |

7000 |

9000 |

10000 |

11000 |

12000 |

130000 |

| 宽≤ |

2285 |

2500 |

3500 |

4500 |

5500 |

6300 |

7000 |

| 高≤ |

1300 |

1800 |

2100 |

2700 |

3000 |

3500 |

3500 |

| 机器总重≤ |

t |

16 |

35 |

54 |

95 |

120 |

150 |

190 |

注1:表中处理能力的确定以下述条件为依据:

a) 热烧结矿温度为750~850℃;

b) 篦板和破碎齿均为新的;

c) 工作情况为连续给料。

注2:表1所列规格系列可根据用户要求特殊设计和开发, 其基本参数按技术协议规定。 |

|