|

CGR型稀土永磁辊式强磁磁选机 Rare

Earth Roll-type magnetic separator

一、简介

I. Profile

永磁辊式强磁磁选机,磁源采用高性能永久磁性材料稀土钕铁硼经聚磁组合而成。具有机型轻,磁场强度高,耗能低,性能稳定,适用性广等优点。

With rare earth roll-type magnetic separators, the magnetic

sources are made up of high-performance permanent magnetism rare earth NdFeB

through magnet. Such separators have advantages such as light weight, high

magnetic intensity, low power consumption, stable performance, wide

applicability, etc.

该机用于贫锰矿石的磁选,每磁选处理一吨锰矿仅需耗电0.2度左右,能一次性将粒度小于15毫米的贫锰矿石富集、提高锰品位3-18度,很好地解决了历年来贫锰矿石不能入炉冶炼,销售难的一大问题。

Such equipment is used for the magnetic separation of lean

manganese ores. Only around 0.2KWH of electricity is needed for the magnetic

separation of one ton of manganese ores. It can gather lean manganese ores with

particle size of less than 15mm

for one time, raise the manganese grade by 3-18, and well solve the problem

that lean manganese ores can not be smelted in furnaces and are not easy to be

sold.

用于稀土矿的磁选、回收,能将盘式磁选机,摇床未能回收的稀土尾矿充分地回收、利用,回收率可达95%以上;用于锆英、金红石、铌钽矿的磁选,能一次性达到磁选目的。

It is used for the magnetic separation and recycle of rare earth

ores, can fully recover and use rare earth tailing not able to be recycled by

disk-type magnetic separators and oscillating tables. The recovery rate can

reach as high as over 95%. It can also be used for the magnetic separation of

zircon, rutile and tantalite. The purpose of magnetic separation can be

achieved once.

二、用途

II. Purpose

该机主要适用于锰矿、稀土矿、铌钽矿、褐铁矿、铬铁矿、钛矿、锆英、独居石、金红石、石榴石、红柱石等矿物的分选、提纯及石英、长石等非金属物料的除铁。

This kind of equipment is mainly used for the separation of ores

such as manganese ores, rare-earth metal ores, tantalite, limonite, chromite,

titanium ores, zirconite, monazite, rutile, garnet and andalusite as well as

the deironing of non-metal materials such as quartz and feldspar.

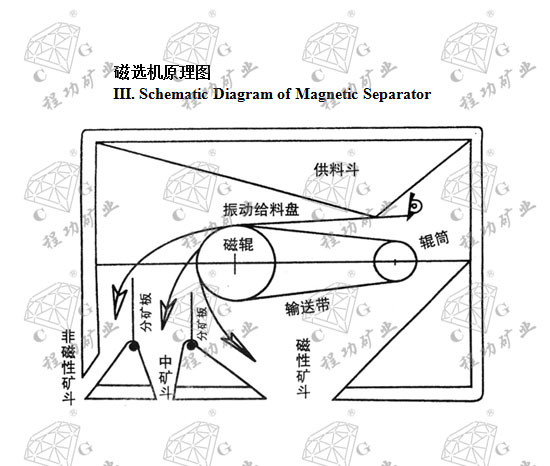

三、磁选机原理图

四、技术参数

1、单辊系列

| 规格 |

磁感应强度 |

传动电机 |

给料电机 |

磁辊转速 |

给料粒度 |

处理能力 |

机重 |

| MT |

|

kw |

r/min |

mm |

t/h |

kg |

| CGRф110×400 |

1100~1450 |

0.37 |

0.24 |

0~300 |

10~0 |

0.6~0.2 |

250 |

| CGRф110×500 |

1100~1450 |

0.37 |

0.24 |

0~300 |

10~0 |

0.75~0.23 |

270 |

| CGRф110×650 |

1100~1450 |

0.37 |

0.24 |

0~300 |

10~0 |

0.1~0.3 |

280 |

| CGRф135×280 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

0.75~0.12 |

270 |

| CGRф135×400 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

1.0~0.18 |

290 |

| CGRф135×500 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

1.3~0.2 |

300 |

| CGRф135×650 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

1.7~0.3 |

300 |

| CGRф160×280 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

0.85~0.13 |

260 |

| CGRф160×400 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

1.4~0.2 |

330 |

| CGRф160×500 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

1.8~0.25 |

390 |

| CGRф160×650 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

2.3~0.35 |

460 |

| CGRф200×280 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

1.4~0.2 |

280 |

| CGRф200×400 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

2~0.3 |

350 |

| CGRф200×500 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

2.5~0.35 |

410 |

| CGRф200×650 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

3.2~0.45 |

480 |

| CGRф240×280 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

1.7~0.25 |

320 |

| CGRф240×400 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

2.5~0.35 |

400 |

| CGRф240×500 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

3~0.45 |

550 |

| CGRф240×650 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

4~0.58 |

650 |

| CGRф380×400 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

3.5~0.5 |

470 |

| CGRф380×500 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

4.6~0.65 |

680 |

| CGRф380×650 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

5.5~0.6 |

790 |

2、双辊系列

| 规格 |

磁感应强度 |

传动电机 |

给料电机 |

磁辊转速 |

给料粒度 |

处理能力 |

机重 |

| MT |

|

kw |

r/min |

mm |

t/h |

kg |

| 2CGRф110×400×280 |

1100~1450 |

0.37 |

0.24 |

0~300 |

10~0 |

0.8~0.23 |

300 |

| 2CGRф110×500×400 |

1100~1450 |

0.37 |

0.24 |

0~300 |

10~0 |

1.1~0.3 |

320 |

| 2CGRф110×650×400 |

1100~1450 |

0.37 |

0.24 |

0~300 |

10~0 |

1.3~0.36 |

360 |

| 2CGRф135×400×280 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

1.5~0.3 |

290 |

| 2CGRф135×500×400 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

1.9~0.4 |

320 |

| 2CGRф135×650×400 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

2.3~0.46 |

350 |

| 2CGRф135×650×500 |

1100~1450 |

0.55 |

0.24 |

0~300 |

15~0 |

2.5~0.5 |

380 |

| 2CGRф160×400×280 |

1100~1450 |

0.37 |

0.24 |

0~300 |

15~0 |

1.95~0.3 |

400 |

| 2CGRф160×500×400 |

1100~1450 |

0.55 |

0.24 |

0~300 |

15~0 |

2.6~0.4 |

460 |

| 2CGRф160×650×400 |

1100~1450 |

0.55 |

0.24 |

0~300 |

15~0 |

3~0.45 |

520 |

| 2CGRф160×650×500 |

1100~1450 |

0.55 |

0.32 |

0~300 |

15~0 |

3.3~0.5 |

580 |

| 2CGRф200×400×280 |

1100~1450 |

0.55 |

0.24 |

0~300 |

15~0 |

2.6~0.35 |

440 |

| 2CGRф200×500×400 |

1100~1450 |

0.55 |

0.24 |

0~300 |

15~0 |

3.4~0.46 |

570 |

| 2CGRф200×650×400 |

1100~1450 |

0.55 |

0.32 |

0~300 |

15~0 |

4~0.54 |

620 |

| 2CGRф200×650×500 |

1100~1450 |

0.75 |

0.32 |

0~300 |

15~0 |

4.4~0.6 |

660 |

| 2CGRф240×400×280 |

1100~1450 |

0.55 |

0.24 |

0~300 |

15~0 |

3.5~0.4 |

520 |

| 2CGRф240×500×400 |

1100~1450 |

0.75 |

0.24 |

0~300 |

15~0 |

4.7~0.5 |

650 |

| 2CGRф240×650×400 |

1100~1450 |

0.75 |

0.32 |

0~300 |

15~0 |

5.5~0.6 |

740 |

| 2CGRф240×650×500 |

1100~1450 |

0.75 |

0.32 |

0~300 |

15~0 |

6~0.7 |

780 |

| 2CGRф380×400×280 |

1100~1450 |

0.55 |

0.32 |

0~300 |

20~0 |

4.5~0.6 |

950 |

| 2CGRф380×500×400 |

1100~1450 |

0.75 |

0.32 |

0~300 |

20~0 |

6~0.77 |

1260 |

| 2CGRф380×650×400 |

1100~1450 |

0.75 |

0.32 |

0~300 |

20~0 |

7~0.9 |

1450 |

五、结构与工作原理

Ⅴ. Structure and Working

Principle

机器由机架、稀土强磁辊筒、料斗、振动给料装置(注:用于细粒易溜矿物的磁选无配此装置)、输送带、不锈钢接料装置、无极调速电机等部件组成。

This kind of machine is composed of frame, rare earth high

intensity drum, hopper, vibrations filling equipment (note: this equipment is

not installed for the magnetic separation of fine-grained easily sliding ores),

conveyor belt, stainless steel material receiving apparatus, stepless speed

regulation motor, etc.

矿料由料斗落入振动给料盘均匀散落的在输料带上,再由输料运送到磁辊上磁选。由于磁性矿物和非磁性矿物经过磁辊时受磁感应力的不同,而落入两个不同的接矿槽中,从而达到矿物分选目的。

Mineral aggregate falls from the hopper to the vibrating feed tray

and spreads evenly on the conveyor belt. Then it is transported from the

conveyor belt to the magnetic roller for separation. Since magnetic minerals

and non-magnetic minerals bear different electromagnetic induction force when

passing the magnetic rollers and thus fall into two different ore-receiving

tanks, the purpose of mineral separation can be achieved.

|