|

试验室CGSL-100型周期式脉动高梯度磁选机

CGSL-100 Cyclic high gradient magnetic separator

一、概述

CGSL-100 周期式脉动高梯度磁选机(以下简称CGSL-100 磁选机),有两种型号,

最高场强分别达到1.2T 和1.75T。该机适用于-1.3 毫米(-200 目占50%~100%)的细粒氧化铁矿、锰矿、黑钨矿、钛铁矿等弱磁性金属矿的湿式分选和黑白钨分离、黑钨与锡石分离,也可用于非金属矿如石英、长石、高岭土等的除铁和提纯。它配有

脉动机构,冲程冲次和背景磁感强度可在较大的范围内连续无级调节,具有富集比大、

分选效率高,不易堵塞,对给矿粒度、浓度和品位的波动适应性强,工作可靠,操作

维护方便等优点。

该机每个选矿周期给矿量100~600 克,可供实验室做小型试验或少量制备矿产品之用。

二、设备构造

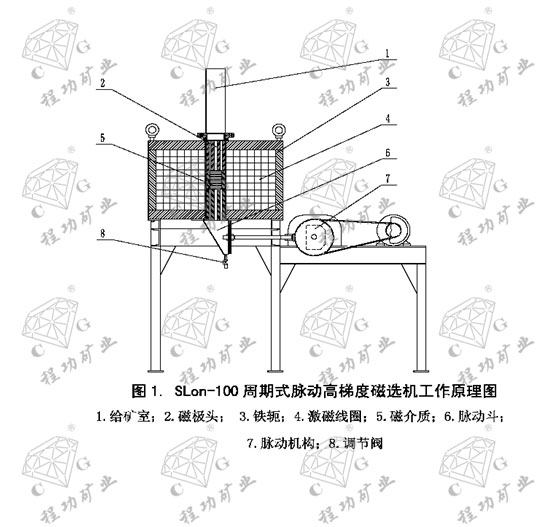

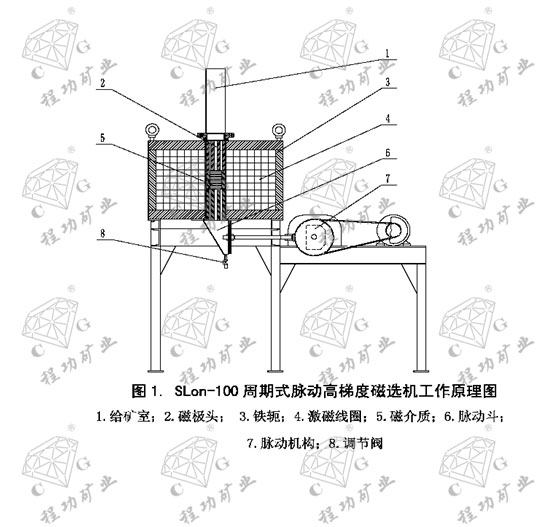

如图1 所示,该机主要由给矿室、磁极头、铁轭、激磁线圈、磁介质、脉动机构、脉动斗、调节阀组成。

1.Introduction

CGSL-100 cyclic pulsating high gradient magnetic separator (we call CGSL-100 for short below) is fit for the wet beneficiation of fine weakly magnetic metallic ore, which grain size is –1.3mm (-200mesh 50%~100%), such as iron oxide, manganese, wolframite and ilmenite, and the separation between wolframite and scheelite and that between wolframite and cassiterite, and deferrization and purification of the non-metallic ore such as quartz, feldspar and kaolin. It is equipped with pulsating mechanism. The pulsating frequency and background magnetic induction could be continuously adjusted in a wide range. It has the advantages of high enrichment ratio, high beneficiation ratio, matrix not easy to be clogged, adaptability for the change of grain size, consistency and grade of the feed, stability for work and convenience for operating and maintaining.

The processing capacity of this machine which could be applied for doing small batch tests in a laboratory or making a little ore product is 100~600 grams in a batch. CGSL-100 has two types which can reach the maximum background magnetic field strength 1.2 Tesla and 1.75 Tesla respectively.

2.Structure

The CGSL-100 cyclic pulsating high gradient magnetic separator mainly consists of feeding box, magnetic pole, magnetic yoke, energizing coils, magnetic matrix, pulsation mechanism, pulsation box and valve.

Fig.1 CGSL-100 cyclic pulsating high gradient magnetic separator

1=feeding box, 2=magnetic pole, 3=magnetic yoke, 4=energizing coils, 5=magnetic matrix, 6=pulsation mechanism, 7=pulsation box, 8=valve.

三、工作原理

选矿时,启动脉动机构,调节好流速,调节激磁电流至所需要的背景磁感强度,

磁介质在磁场中被磁化,其表面形成高梯度磁场,将充分搅拌松散的矿浆从给矿室给入,沿上磁极头的孔洞流入分选腔,矿浆中的磁性颗粒被吸着在磁介质表面。非磁性颗粒沿下磁极头的孔洞流入脉动斗排走。每周期给矿完成后,可加入适量清水漂洗精矿,以进一步提高磁性物纯度,然后切断激磁电源,用清水将磁性物冲洗出来,即完

成一个周期的选矿。

3. Principle of Operation

Start the pulsation mechanism and adjust the velocity of the feeding and the background magnetic induction to the needed value before doing the batch test. The background magnetic induction can be controlled by adjusting the energizing current. When electricity is given to the energizing coils, a magnetic field will be built up. And the matrixes in the magnetic field are magnetized with high gradient magnetic field formed around them. Feed the incompactly stirred slurry through the holes of upper magnetic pole into the separating zone from the feeding box. The magnetic particles of the slurry can be attached onto the surface of the matrix, and non-magnetic particles enter into the pulsation box by the holes of lower magnetic pole and then are discharged. Put in some water for rinsing the concentrates in order to upgrade magnetic particles after one batch testing. Then shut off the energizing power and use clean water to wash out the magnetic particles, one batch testing is done.

四、规格型号和主要参数 Specifications and Parameters

| 型号规格Model |

单位

Uite |

CGSL-100

(背景场强0~1.75T) |

CGSL-100

(背景场强0~1.2T) |

分选腔直径×高度

Diameter×Height of

separating cavity |

mm |

Φ100×100 |

Φ100×100 |

| 背景磁感强度Background field |

T |

0~1.75 |

0~1.2 |

| 激磁电流 Energizing current |

A |

0~1900 |

0~1200 |

| 激磁电压 Energizing Voltage |

V |

0~30 |

0~16.4 |

| 激磁功率 Energizing Power |

kw |

0~57 |

0~19.7 |

| 脉动电动机功率 Pulsating Power |

kw |

0.55 |

0.55 |

| 脉动冲程 Pulsating stroke |

mm |

0~30 |

0~30 |

| 脉动冲次 Pulsating times of stroke |

r/min |

0~600 |

0~600 |

| 磁介质堆尺寸(直径×高)Size |

mm |

Φ100×10

(62.4×62.4×100) |

Φ100×100

(62.4×62.4×100) |

给矿粒度(-200目%)

Ore-Feeding size |

mm |

-1.3(50~100) |

-1.3(50~100) |

| 给矿浓度 Ore-Feeding density |

% |

5~40 |

5~40 |

| 给矿量 Capacity |

g/cycle |

100~600 |

100~600 |

| 供水压力 Water pressure |

MPa |

0.1~0.3 |

0.1~0.2 |

| 主机外形尺寸Overall dimensions |

mm |

1750×1180×1720 |

1600×800×1600 |

| 主机重量 Weight |

kg |

1350 |

1150 |

|