|

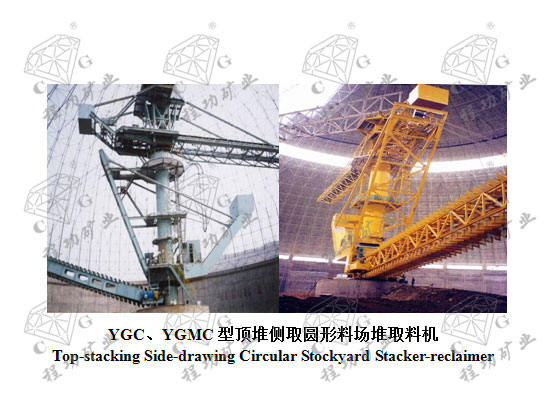

YGC、YGMC型顶堆侧取圆形料场堆取料机

Top-stacking

Side-drawing Circular Stockyard Stacker-reclaimer

顶堆侧取圆形堆取料机是北方重工沈矿集团为适应火力发电、建材、煤炭、冶金等行业贮煤场工程,近几年研制、设计的一种堆取料机械设备。

Top-stacking side-drawing

circular stockyard stack-reclaimer is a kind of stacking and reclaiming

machinery equipment developed and designed by Northern Heavy Industry Shenyang

Mining Machinery Group in recent years to meet the requirement of coal yard

projects in thermal power generation, building material, coal, metallurgy and

other industries.

目前,国内电厂、建材、煤炭、冶金等贮煤场广泛应用斗轮式堆取料机。北方重工沈矿集团开发研制的顶堆侧取式圆形堆取料机与之比较有如下特点:

At present, bucket wheel

stacker-reclaimers are widely used in coal yards of power plants, building

material, coal and metallurgy industries. Compared with them, the top-stacking

side-drawing circular stacker-reclaimers developed by Northern Heavy Industry

Shenyang Mining Machinery Group have the following advantages:

1.占地面积小:与同等贮量料场相比可节省占地面积40%~50%。

1. They occupy small areas.

They occupy 40%~50% less area than those of stockyard with equal reserve.

2.机械制造造价费用低:与同等贮量、相同功率设备比较,制造费用可降低20%~40%左右。

2. They spend low manufacturing

expenses. Compared with equipment with equal reserve and same power, they use

around 20%~40% less manufacturing expenses.

3.有效保证原料成分均匀稳定:圆形堆取料机辅以厂房建筑,适用于室内操作。具有防水、防雨雪、防风沙功能,保证原料成分、湿度稳定。促使后次工序设备出力功率充足,运转平稳。

3. They can effectively ensure

the material components are even and stable. Circular stacker-reclaimer applies

to being operated in plant buildings. They can resist water, rain and snow, as

well as sand so as to ensure the components of materials and stable humidity.

The equipment can maintain sufficient power and run smoothly in the following working

procedures.

4.具有环保功能:圆形料场外围建有挡墙,以增加贮量。挡墙上装有半球状网架屋顶,可将堆取料机作业过程中产生的扬尘封闭在设定的空间内。

4. They are environmentally

friendly. Retaining walls are built outside the circular stockyard to increase

storage. The retaining walls are equipped with hemispheric grid roofs which can

enclose dust produced during the operation of stacker-reclaimer within defined

space.

圆形料场混匀堆取料机主要由可回转的悬臂堆料机、中柱、侧式刮板取料机、电控系统等组成。中柱安装在圆形料场中心,中柱上部安装有可回转的悬臂堆料机,悬臂堆料机可绕中柱360°回转,通过回转机构来实现锥壳法堆料作业。取料机是一台绕中柱回转的侧式刮板取料机,通过取料机臂架上往复运动的刮板,将料堆物料逐层刮落至中柱下面的出料漏斗,通过漏斗将物料卸至地下的带式输送机运出堆场。该设备可连续进行堆、取料作业,并全自动操作。该设备在完成初始料堆后,实行位移3°的锥壳法堆料方式,在取料机取料过程中始终保留残余料堆以使锥壳法堆料方式能够最大限度降低落料扬尘。

Circular stockyard blending

stacker-reclaimer is mainly composed of rotatable boom stacker, central pillar,

side-type scrapper reclaimer, electric control system, etc. The central pillar

is installed in the center of the circular stockyard. The top of the central

pillar is equipped with rotatable boom stacker which can rotate 360°around the

central pillar. It realizes material stacking by conical shell method through

slewing mechanism. The reclaimer is a side-type scraper reclaimer which rotates

around the central pillar. It scrapes the stacking materials in the material

pile layer by layer till the discharge hopper below the central pillar through

the scrapper which moves back and force on the reclaimer boom. Then through the

hopper, it discharges the materials to the belt conveyor and then conveys them

out of the stockyard. This equipment can stack and reclaim materials

continuously and is operated fully automatically. After it finishes initial

material stacking, it implements material stacking by conical shell method with

a displacement of 3°. During the process of reclaiming, the residual material

piles are left unchanged so that dust appearing during falling of materials can

be minimized through conical shell material stacking.

根据主机及工艺要求,堆料机和取料机控制系统采用自动、手动、维修三种控制方式。

According to the mainframe and

technological requirements, the control system of stacker and reclaimer adopts

three control modes, i.e. automatic control, manual control and maintenance

control.

自动控制方式:在堆、取料机备妥状态下,由中央控制室发起停指令,进行自动控制。在自动控制状态下,起动顺序是按照堆、取设备要求顺序起机,并进入自动堆或取的工作状态。同时完成对系统故障的自动监测、报警、自动停机。在自动控制方式下,停机顺序是:自动起机的相反顺序。

Automatic control mode: When

the stacker-reclaimer is ready, the central control room gives start and stop

instructions for automatic control. Under the automatic control state, the

sequence of start follows the requirements of stacking and reclaiming

equipment. Besides, it enters the working state of automatic stacking or reclaiming.

At the same time, the automatic monitoring and alarm of system failures as well

as automatic shutdown are finished. Under the automatic control mode, the

shutdown sequence is opposite to the startup sequence.

手动控制方式:手动控制方式在操作台上进行适应于调试过程及堆、取料机换堆和调车到指定堆、取料开始点,可完成各单元的单步操作。

Manual control method: Manual

control is placed on the operation station. It applies to debugging process and

stacker-reclaimer’s stack changing and shunting to the designated starting

points of stacking and reclaiming. With it, the operation of each step can be

finished.

维修控制方式:适应于现场维修,但操作按钮安装有利于维修操作位置,只能现场操作。

Maintenance control method; this

method applies to on-site maintenance. The installation of operation button

facilities the maintenance of operating position. It can only be operated on

the scene.

为保证硬件设备的可靠性,堆取料机所选配的可编程控制器( PLC)、变频器、智能马达控制器等主要元器件均为美国 A-B公司产品。而堆料机的料位检测装置选用德国公司原装产品。

To ensure the reliability of

hardware equipment, the main components such as programmable logic controller (PLC),

frequency converter, and intelligent motor controller selected for

stacker-reclaimer are all products manufactured by AB Company in US. The

material level detector of stacker is the original product manufactured by the

company in Germany .

顶堆侧取圆形堆取料机技术参数表

| 型号 |

名称 |

堆料机 |

取料机 |

适用物料 |

贮存能力m3 |

控制方式 |

| 堆料能力t/h |

带宽mm |

取料能力 t/h |

刮板宽/链速 mm/m/s |

| YGC ××/60 |

顶堆侧取圆形

料场堆取料机 |

500-800 |

~650-1000 |

40-400 |

~1800/0.5 |

煤、石灰石、页岩、铝矾土、及其它散状物料 |

30000 |

自动控制手动控制 |

| YGMC ××/60 |

| YGC ××/80 |

500-800 |

~650-1200 |

60-600 |

~1800/0.6 |

56000 |

| YGMC ××/80 |

| YGC××/90 |

500-1000 |

~800-1200 |

80-800 |

~1800/0.6 |

75000 |

| YGMC ××/90 |

| YGC ××/100 |

1000-2000 |

~800-1400 |

200-1800 |

~2000/0.6 |

100000 |

| YGMC ××/100 |

| YGC××/110 |

1600-2400 |

~800-1400 |

240-2400 |

~2200/0.7 |

140000 |

| YGMC ××/110 |

| YGC ××/120 |

2000-3500 |

~800-1600 |

400-3500 |

~2500/0.7 |

200000 |

| YGMC ××/120 |

标记示例:

1.堆料能力1500t/h,取料能力2000t/h,料场直径120m 的煤料场圆形料场顶堆侧取堆取料机:YGC2000/120顶堆侧取堆取料机

2.堆料能力1600t/h,取料能力600t/h,轨道直径100m 的煤料场圆形料场门式顶堆侧取堆取料机:YGMC600/100门式顶堆侧取堆取料机

Example of Symbol

1. Stacking capacity: 1,500 t/h; reclaiming capacity: 2,000 t/h,

circular coal stockyard top-stacking side-drawing stacker-reclaimer with the

stockyard diameter of 120m: YGC2000/120

top-stacking side-drawing stacker-reclaimer

2. Stacking capacity: 1,600 t/h; reclaiming capacity: 600 t/h,

circular coal stockyard portal-type top-stacking side-drawing stacker-reclaimer

with the track diameter of 100m:

YGC600/100 portal-type top-stacking side-drawing stacker-reclaimer

|