|

FG、FC型螺旋分级机 Spiral classifier

国家行业标准 JB/T 53601

一、用途

该系列分级机适用于矿石、非金属物料进行脱水、脱介、脱泥和干湿式分级。

This classfiers suitable for dewatering,medium,drainaging amd spraying in ore clressing for medium and fine naterial wet and dry classifying in mine.

本机主要用于金属选矿的生产流程中,依矿物颗粒泥降速度的不同,将14-325网目的矿石进行粒度分级,也可以以矿石中分出废泥或用于矿砂的脱水。

Such machine is mainly used in the production flow of metal processing. According to the difference in sedimentation rate of mineral particles and mud, the particle sizes of ores with 14-325 meshes are classified. Waste mud or water for ore sand can be separated from the ores.

二、机器的技术规范

本机根据螺旋数量的不同,有单螺旋和双螺旋之分,同时还有高堰式和沉没式的区分,如溢流边堰高于螺旋轴中心线,且低于溢流端部螺旋的外径则为高堰式;如溢流边堰高于螺旋轴中心线,同时还高于溢流端部的螺旋的外径则为沉没式:高堰式分级机一般用于100网目粒度以下的分级,沉没式分级机一般用于200网目粒度以下的分级.

Such machines are divided into single spiral classifiers and double spiral classifiers. Beside, they are also divided into high weir spiral classifiers and submerged spiral classifiers. If the overflow edge is higher than the center line of spiral shaft and lower than the external diameter of spiral at the overflow end, the spiral classifiers are high weir ones. If the overflow edge is higher than the center line of spiral shaft and also higher than the external diameter of spiral at the overflow end, the spiral classifiers are submerged ones. High weir classifiers are usually used for the classification with particle size of below 100 meshes. Submerged classifiers are usually used for the classification with particle size of below 200 meshes.

三、技术参数

型号

规格

Model |

螺旋直径

Spiral Dia. |

螺旋转速

Spiral Speed |

产 量Output |

配套电机功率Motor Power |

重量

Weight |

| 返砂量 Circulating Load |

溢流量 Overflow Quantity |

升降 Lift Lower |

传动

Drive |

| mm |

r/min |

t/24h |

t/24h |

kw |

kw |

t |

| 高堰式单螺旋分级机High-weir single spiral classifier |

| FG-3 |

Φ300 |

8.3-2.2 |

30-80 |

10-30 |

2.2 |

1.1 |

0.67 |

| FG-5 |

Φ500 |

8.5-15.5 |

143-261 |

32 |

2.2 |

1.1 |

1.6 |

| FG-7 |

Φ750 |

4.5-9.9 |

256-564 |

65 |

2.2 |

3 |

2.83 |

| FG-10 |

Φ1000 |

3.5-7.6 |

473-1026 |

85 |

2.2 |

5.5 |

4 |

| FG-12 |

Φ1200 |

5、6、7 |

1170-1600 |

155 |

2.2 |

5.5 |

8.54 |

| FG-15 |

Φ1500 |

2.5、4、6 |

1140-2740 |

235 |

2.2 |

7.5 |

11.68 |

| FG-20 |

Φ2000 |

3.6、5.5 |

3890-5940 |

400 |

3 |

11、15 |

20.45 |

| FG-24 |

Φ2400 |

3.64 |

6800 |

580 |

3 |

15 |

25.65 |

| FG-30 |

Φ3000 |

3.2 |

11650 |

893 |

4 |

22 |

40.9 |

| 高堰式双螺旋分级机High-weir double spirals classifier |

| 2FG-12 |

Φ1200 |

5、6、7 |

2340-3200 |

310 |

2.2×2 |

5.5×2 |

15.84 |

| 2FG-15 |

Φ1500 |

2.5、4、6 |

2280-5480 |

470 |

2.2×2 |

7.5×2 |

21.11 |

| 2FG-20 |

Φ2000 |

3.6、5.45 |

7780-11880 |

800 |

3×2 |

22、30 |

36.34 |

| 2FG-24 |

Φ2400 |

3.67 |

13600 |

1160 |

3×2 |

30 |

53.49 |

| 2FG-30 |

Φ3000 |

3.2 |

23300 |

1785 |

4×2 |

40 |

73.03 |

| 2FG-38 |

Φ3800 |

3 |

33000 |

3400 |

11×2 |

55×2 |

125 |

| 沉没式单螺旋分级机Submerged single spiral classifier |

| FC-12 |

Φ1200 |

2.5、4、6 |

1170-1630 |

120 |

2.2 |

7.5 |

11.1 |

| FC-15 |

Φ1500 |

2.5、4、6 |

1140-2740 |

185 |

2.2 |

7.5 |

15.32 |

| FC-20 |

Φ2000 |

3.6、5.5 |

3890-5940 |

320 |

3 |

11、15 |

29.056 |

| FC-24 |

Φ2400 |

3.64 |

6800 |

455 |

4 |

18.5 |

37.267 |

| FC-30 |

Φ3000 |

3.2 |

11650 |

705 |

4 |

22 |

46.2 |

| 沉没式双螺旋分级机Submerged double spiral classifier |

| 2FC-12 |

Φ1200 |

3.8、6 |

1770-2800 |

240 |

2.2×2 |

7.5×2 |

19.61 |

| 2FC-15 |

Φ1500 |

2.5、4、6 |

2280-5480 |

370 |

2.2×2 |

7.5×2 |

27.45 |

| 2FC-20 |

Φ2000 |

3.6、5.5 |

7780-11880 |

640 |

3×2 |

22;30 |

50 |

| 2FC-24 |

Φ2400 |

3.67 |

13700 |

910 |

3×2 |

30 |

53.491 |

| 2FC-24 |

Φ2400 |

3.67 |

13700 |

910 |

4×2 |

37 |

65.283 |

| 2FC-30 |

Φ3000 |

3.2 |

23300 |

1410 |

4×2 |

45 |

84.87 |

注:(1)表中C—代表沉没式,G代表高堰式;2F—代表双螺旋,F—代表单螺旋;(2)表载计算生产量是根据矿石比里,溢流粒度、螺旋转数、螺旋直径等因素按经验公式计算得出。

Note: (1) In the table, C represents submerged type, G represents high weir type, 2F represents double spiral type, and F represents single spiral type. (2) The production capacity in the table is figured out based on empirical formula according to factors such as overflow particle size, revolution speed of screw and screw diameter in ore ratio.

四、机器的结构说明

3、总体说明

本机系由传动装置、螺旋(左、右)水槽、升降装置、下部支座、润滑装置、排矿阀和进料口等部组成。(详见附后总图)

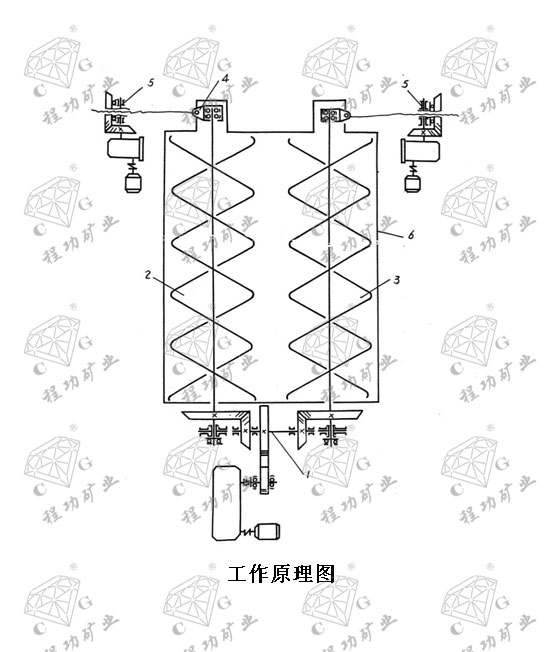

本机水槽成倾斜安置,其倾斜角大小根据工艺流程中设备配置情况确定,由传动装置带动的螺旋(左、右)在槽内回转,经磨细的矿浆从侧面进料口进入槽内,则在槽的下端形成一个矿浆沉淀区,其表面积和容积决定于水槽倾斜角大小和溢流边堰高度,低速回转的螺旋能起一定的搅拌作用,矿浆经搅拌后,轻、细颗粒浮于上面成为溢流,由溢流边堰溢出,流入下一道选矿工序;粗重的颗粒沉于槽底,成为返砂,由螺旋运输到排矿口排出,其工作原理见图1。

如果磨矿与分级是闭路循环作业,则由排矿口排出的返砂,仍进入磨机再磨细,分级机通常是与磨机配置在一起成闭路循环工作的。

IV. Structure Description

1. General Description

This kind of machine is composed of transmission mechanism, (left, right) spiral water tank, lifting device, lower support, lubricating device, ore discharge valve, feed inlet, etc (See the attached general drawing for details).

The water tank of this machine is installed obliquely. The angle of inclination is determined according to equipment configuration of equipment in the process flow. The (left, right) spirals driven by the transmission mechanism rotates in the water tank. The finely grained slurry enters the water bank from the feed inlet at one side and forms one slurry precipitation zone, whose surface area and volume depends on the value of the water tank’s inclination angle and the height of overflow edge. The spirals rotating at a low speed play a certain stirring role. After the slurry is stirred, the light and fine particles float above the surface and overflow from the overflow edge. Then they flow into the next working procedure of ore dressing. The heavy and thick particles sink into the bottom of the water tank and become return sand which is transported by the spirals to the ore discharge mouth for discharge.

If ore grinding and classification are closed loop operation, the return sand discharged from the ore discharge mouth still goes into the mill for further grinding. Classifiers normally form closed loop operation together with mill.

Function Diagram

1、传动装置 2、左螺旋 3、右螺旋 4、下部支座 5、升降装置 6、水槽

1. Transmission mechanism 2. Left spiral 3. Right spiral 4. Lower support

5. Lifting Device 6. Water tank

4、主要部件结构说明:

(1)传动装置:Ф3000,Ф2400,Ф2000分级机是由电动机、联轴节、减速器联轴节圆柱和伞齿轮副构成;Ф1500,Ф1200分级机则由电动机、三角皮带、减速器圆柱齿轮副构成;它带动螺旋回转。

(2)螺旋(左、右):由空心轴、支架、螺旋叶片、衬铁等组成、上端支承在十字轴套内、下端支承在下部支座内、空心轴走直径Ф500㎜以上的用二个半圆形通长钢板焊接成,免除了由于横向焊缝的焊接质量,使轴产生折断事故。小直径的空心轴(Ф325)采用无缝钢管。当螺回转时,螺旋叶面对矿浆起微小的搅拌作用,轻、细的颗粒由溢流堰口排出,况底的粗,重颗粒由螺旋输送到排矿口排出。衬铁采用耐磨寿命是重大关键问题,尚须进行研究解决。

(3)下部支座:因其长期浸没在矿浆内工作,因此密封是关键问题,密封的好环直接影响轴承使用寿命,在设计上采用多层棉纱发瓣式盘根和高压油脂双重密封结构,并在润滑装置上配置手动干油泵,可以定期往轴承内压注油脂,以保持其密封性能。

(4)水槽:由钢极、各种型钢焊接成。由于运输等问题Ф3000,Ф2400,Ф2000分级机的水槽,在工地进行总装焊接。水槽内盛有全部,并承受机器本身重量和全部负荷,为此支承水槽的地基设计分重要(结构要合适、基础要牢固。)为避免因支承不当造成水槽变形影响机器的运转起见,本机附有地基结构示意图,可作为地基设计的参考依据。

(5)润滑装置:为善机器的润滑条件,加强下部支座轴承的润滑和密封性能Ф3000、Ф2400、Ф2000分级机故采用手动集中润滑,配置了手动于油泵和操纵阀门,可以定期向各轴承内压注油脂,润滑操纵部分用户可根据具体操作条件确定安装在水槽的右侧壁上或右侧壁上,也可另外设置操纵台Ф1200、Ф1500分级采用手动润滑方式。

(6)放水阀:为了必要时能从水槽内排出矿浆,在水槽下部设有放水阀,可随时将矿浆排出,正常生产时可关阀。

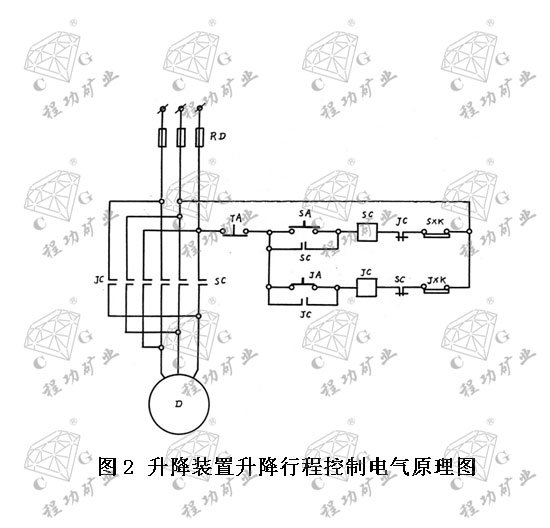

(7)升降装置:它由电机、轮减速器、伞齿轮副、丝母、比等零部件组成,当分级机停止工作时,为避免矿浆内固体沉淀压住螺旋,产生负荷损伤机件起见,以及检修工作上的需要,故设有升降装置。当分级机停车时必须把螺旋由水槽中提起,使大部分螺旋离开矿浆,为保证升降作业的安全,专备有行程终点开关,使升降行程能自行控制,其电气原理图参见图2

另外还特设计有螺旋分级机转动和升降联动控制电气原理理图(图6)当分级机停车时升降装置启动能自动将螺旋提升至一定高度,分级机工作时升降装置把转动能自动将螺旋下降至工作位置这样可保持传动零部件的寿命,防止空心轴因过负荷而折断,。是否需要装设联动控制电气装置,用户可根据具体条件确定、制造厂不供应本电气装置所需的零部件。

4. Structure Description of Main Parts

(1) Transmission mechanism: Ф3000, Ф2400 andФ2000 classifiers consist of motor, coupling, speed reducer coupling cylinder and bevel gear pair whileФ1500 andФ1200 classifiers consist of motor, V-belt, and speed reducer cylinder gear pair. The transmission mechanism drives the rotation of spiral.

(2) (Left, right) spirals: Spirals consist of hollow shaft, bracket, spiral vane, iron liner, etc. The upper ends are supported in the cross-shaft sleeves while the lower ends are supported in the lower support. Hollow shafts whose diameter is over 500mm are welded with two semicircular long steel plates so that shaft fracture due to poor welding quality caused by transverse weld can be avoided. For hollow shafts with small diameters (such as 325mm), seamless steel pipes are used. When the spirals are rotating, the spiral vanes stir the slurry slightly. The light and fine particles are discharged from the overflow weir while the heavy and thick particles are conveyed to the ore discharge mount for discharge. Anti-wear life of iron liner is very important. It needs further study.

(3) Lower support: As lower support long operates submerged in the slurry, its sealing is very important. The sealing of lower support directly affect the service life of bearings. In design, it is of the multilayer cotton yarn valve-clack type packing and high-pressure grease double seal structure, and is equipped with manual dry pumps on the lubricating device. It can fill grease to the inside of bearings on a regular basis to maintain its sealing property.

(4) Water tank: Water tank is welded through steel poles and all kinds of profile steel. Due to difficulty in transportation, the water tanks ofФ3000, Ф2400 andФ2000 classifiers are generally assembled and welded at the workplace. The water tank shall bear the weight of the machine itself and all load. Therefore, the design of foundation supporting the water tank is very important (the structure should be reasonable and the foundation shall be firm). To avoid the water tank becomes deformed due to improper supporting and thus affect the operation of machine, the diagram of foundation structure is attached for this machine which can serve as the reference basis for foundation design.

(5) Lubricating device: To improve the lubricating conditions of machines and better the lubricating and sealing property of lower support bearings, the lubrication method of manual centralization lubrication is adopted forФ3000, Ф2400 andФ2000 classifiers. It is equipped with manual dry pumps and operating valve and can infuse grease to the insides of all bearings on a regular basis. Some users can decide if the lubricating control console is installed along the left wall or right wall according to specific operating conditions. Or it can be installed otherwise. The lubrication method of manual lubrication is adopted forФ1200 andФ1500 classifiers.

(6) Drain valve: Drain valve is installed at the lower of the water tank so that slurry can be discharged from the water tank when necessary. During normal operation, the valve can be shut off.

(7) Lifting device: The lifting device consist of motor, wheel reducer, bevel gear pair, nut with thread, and other parts. When the classifier stops working, lifting device is installed with an aim to preventing the solid in the slurry from precipitating and pressing the spirals so as to damage machine parts as well as facilitating repair work. When the classifier stops working, the spirals must be lifted from the water tank to get most of the spirals away from the slurry. For the safety of lifting operation, stroke end switch is installed so that the lifting journey can be controlled automatically. See Figure 2 for Electrical Schematic Diagram.

Besides, electrical schematic diagrams for spiral classifier rotation and lifting linkage control are designed (Figure 6). When the classifier stops working, with the startup of lifting device the spirals can automatically be lifted to a certain height. When the classifier is working, the spirals can be automatically lowered to the working position during the rotation of lifting device to keep the hollow from being fractured due to overload. Whether to install linkage control electric device shall be determined by the user according to actual conditions. The manufacturer does not provide parts and components required by this electric installation.

Figure 2: Electrical Schematic Diagram of Lifting Journey Control of Lifting Device

RD-熔断器 TA-停止按灯 SC-提升用接触器

SXK-提升行程开关 JC-下降用接触器 JXL-下降行程开关 JA-下降起动

RD – Fuse TA – Stop light

SC – Contactor for lifting SXK – Lifting journey switch

JC – Contactor for lowering JXL – Lowering journey switch

JA – Lowering startup

|