|

CGSL

立环脉动高梯度磁选机

CGSL

Vertical Ring and Pulsating High Gradient Magnetic Separator

一、概述

CGSL系列立环脉动高梯度磁选机(以下简称CGSL强磁机)包括CGSL-3000、CGSL-2500、CGSL-2000、CGSL-1750、CGSL-1500、CGSL-1250、CGSL-1000,CGSL-750,CGSL-500等规格,其额定背景磁感应强度为1.0T, 适应于-1.2毫米(-200目占30~100%)的细粒氧化铁矿(赤铁矿、褐铁矿、菱铁矿等)、锰矿、钛铁矿、黑钨矿等多种弱磁性金属矿的湿式分选和黑白钨分离、黑钨与锡石分离,也可用于非金属矿如石英、长石、霞石矿的除铁等方面。其转环立式转动,反冲精矿,并配有脉动机构。它具有富集比大、分选效率高、不易堵塞、对给矿粒度、浓度和品位的波动适应性强、工作可靠,操作维护方便等优点。

CGSL立环脉动高梯度中磁机(以下简称CGSL中磁机),其额定背景磁感强度为0.4-0.6T,包括CGSL-1500、CGSL-1750、CGSL-2000、CGSL-2500等规格,适用于处理粒度较粗的氧化铁矿、钛铁矿等中等磁性的矿石。在鞍钢工业应用证明,作为红铁矿粗粒级的抛尾设备具有处理量大、尾矿品位低、可调性好、工作稳定、性价比高的优点。

1. Introduction

CGSL Vertical ring and Pulsating High Gradient Magnetic Separators (we call CGSL VPHGMS for short below) include CGSL-3000,

CGSL-2500, CGSL-2000, CGSL-1750, CGSL-1500, CGSL-1250, CGSL-1000, CGSL-750

and CGSL-500. Their rated

background magnetic field is 1.0T (Tesla). They are efficient equipments for processing fine, weakly magnetic minerals, such as

hematite, limonite, wolframite, ilmenite, manganese, tantalum-niobium, and it

can be also applied for cleaning non-metallic minerals, such as Quartzes, Fluorspars and Nephelines. Its separating ring with

matrix rotates vertically and flushing direction of magnetic products is

opposite to that of feeding. A pulsating mechanism is located below the

separating zone. The CGSL separator has the advantages

of large beneficiation ratio, high recovery, non-blocking/plugging of the

matrix, easy adaptability to different particle sizes, density and grade, good

reliability, and it is convenient to operate and maintain.

CGSL Vertical ring and Pulsating Medium Intensity

Magnetic Separators (we call CGSL VPMIMS for short) include CGSL-1500、CGSL-1750、CGSL-2000 and CGSL-2500. Their rated background magnetic field is 0.4-0.6T

(Tesla). They are fit for processing medium magnetic materials like oxidized iron

ore and ilmenite with more coarse size. The industrial application in Anshan

Steel Company proves that it has the advantages of larger capacity, low tail grade, stable performance and high

price-performance ratio.

二、设备构造

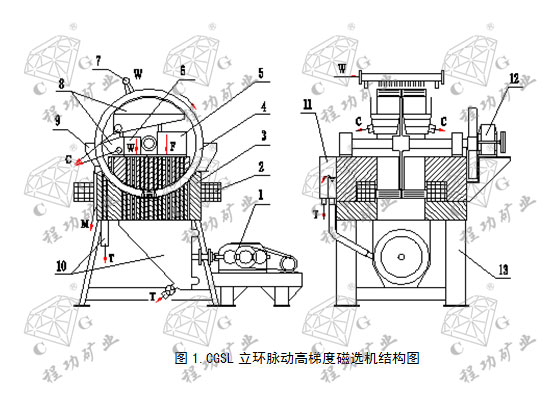

如图1所示,CGSL磁选机主要由脉动机构、激磁线圈、铁轭、转环和各种矿斗、供水装置等组成。

2. Structure

The CGSL

separator consists mainly of the pulsating mechanism, energizing coils,

magnetic yoke, separating ring, feed and product boxes as shown in Fig. 1.

1、脉动机构 2、激磁线圈 3、铁轭 4、转环 5、给矿斗 6、漂洗水斗 7、精矿冲洗装置

8、精矿斗 9、中矿斗 10、尾矿斗 11、液位斗 12、转环驱动机构 13、机架

F-给矿 W-清水 C-精矿 M-中矿 T-尾矿

Fig. 1. CGSL vertical

ring and pulsating high gradient magnetic separator

1-Pulsating

mechanism 2-energizing coils 3-magnetic yoke 4-separating ring 5-feeding box 6-wash water box

7-concentrate flush 8-concentrate

box 9-middling chute 10-tailings box 11-slurry level box 12-ring driver 13-support frame

F-feed W-water C-concentrate M-middling T-tailings

三、工作原理

转环内装有导磁不锈钢棒或钢板网磁介质(也可根据需要充填导磁不锈钢毛等磁介质)。选矿时,转环作顺时针旋转,矿浆从给矿斗给入,沿上铁轭缝隙流经转环,转环内的磁介质在磁场中被磁化,磁介质表面形成高梯度磁场,矿浆中磁性颗粒被吸着在磁介质表面,随转环转动被带至顶部无磁场区,用冲洗水冲入精矿斗中,非磁性颗粒沿下铁轭缝隙流入尾矿斗中排走。

转环立式旋转的优点是:如果给矿中有粗颗粒不能穿过磁介质堆,一般会停留在磁介质堆的上表面,即靠近转环内圆周,当磁介质堆被转环带至顶部时,正好旋转了180°,粗颗粒位于磁介质的下部,很容易被精矿冲洗水冲入精矿斗。

当鼓膜在冲程箱的驱动下作往复运动时,只要矿浆液面高度能浸没转环下部的磁介质,分选室的矿浆便作上下往复运动,脉动流体力使矿粒群在分选过程中始终保持松散状态,从而有效地消除非磁性颗粒的机械夹杂,显著地提高磁性精矿的品位,此外,矿浆脉动显然对防止磁介质的堵塞也大有好处。

为了保证良好的分选效果,使脉动充分发挥作用,维持矿浆液面高度至关重要,该机的液位调节可通过调节尾矿斗下部尾矿阀、给矿量或漂洗水量实现。该机还有一定的液位自我调节能力,当外部因素引起液面升高时,尾矿的排放有尾矿斗下部阀门和液位斗溢流面两种通道;当液面较低时,液位斗不排尾矿,尾矿只能从尾矿斗下部阀门排走,此外,液面较低时液面至尾矿阀的高差减小,压力降低,尾矿流速自动变慢。液位斗的液面与分选区的液面同样高,它既能起到自我调节作用,又能供操作者随时观察液位高度。当给矿量有20%波动时,该机靠本身的自我调节能力稳定液位。如果给矿量的波动很大,用户应在给矿前面安装一个恒压箱,让多余的矿浆流回泵池或浓密池,使CGSL磁选机给矿量的波动小于20%。

3. Principle of Operation

Along the periphery of the

ring there is a number of rectangular chambers in which the matrix of the

expanded metal sheets or rods made of magnetic stainless steel are placed. When

the separator is in operation, the ring rotates clockwise as seen from the

access side. The slurry fed from the feed box enters the ring through slots in

the upper yoke. The matrix in the working zone is magnetized. The magnetized

particles are attracted from the slurry onto the surface of the matrix, then

brought to the top of the machine where the magnetic field is negligible, and

are then flushed out into the concentrate box.

The non-magnetic particles

pass through the matrix and enter the tailing box through slots in the lower

yoke under the combined action of slurry pulsation, gravity and hydrodynamic

drag. The pulsating mechanism drives the rubber diaphragm on the tailing box so

that it moves back and forth. As long as the slurry level is adjusted to be

above the fixed level in the slurry level box, kinetic energy due to the

pulsation can be effectively transmitted to the separating zone.

As the flushing direction of discharging

the magnetic fractions is opposite to that of the feed, relative to each matrix

stack, coarse particles can be flushed out without having to pass through the

entire depth of the matrix. The slurry pulsation keeps particles within the

matrix in a loose suspended state all the time. The reverse flush and the

slurry pulsation prevent matrix clogging. Additionally, the pulsation improves

the quality of the concentrate with respect to grade.

These factors not only

ensure the effective recovery of weakly magnetic particles as small as 0.01 mm, but also extend the size range of

the feed material up to 1.2 mm,

thus increasing the upper limit of the particle size to be treated.

四、规格型号和主要参数(CGSL强磁机) Specifications and Parameters (CGSL

VPHGMS)

| 型号规格Model |

单位Uite |

CGSL-500 |

CGSL -750 |

CGSL -1000 |

CGSL -1250 |

| 转环外径Ring diameter |

mm |

500 |

750 |

1000 |

1250 |

转环转速

Rotating speed of Ring |

r/min |

0.3-3 |

0.3-3 |

2-4 |

2-4 |

给矿粒度

Ore-feeding size |

mm |

≤1.0 |

≤1.0 |

≤2 |

≤2 |

给矿浓度

Ore-feeding concentration |

% |

10-40 |

10-40 |

10-40 |

10-40 |

矿浆通过能力

Slurry put through |

m3/h |

0.5-1.0 |

1.0-2.0 |

12.5-20 |

20-50 |

| 干矿处理量Capacity |

t/h |

0.03-0.125 |

0.06-0.25 |

4-7 |

10-18 |

额定背景场强

Background Field |

T |

1.0 |

1.0 |

1.0 |

1.0 |

额定激磁电流

Energizing current |

A |

1300 |

1200 |

1050 |

1000 |

额定激磁电压

Energizing Voltage |

V |

12.3 |

23 |

27.3 |

35 |

额定激磁功率

Energizing Power |

kw |

16 |

22 |

28.6 |

35 |

转环电动机功率

Ring Power |

kw |

0.37 |

0.55 |

1.1 |

1.5 |

脉动电动机功率

Pulsating Power |

kw |

0.37 |

0.75 |

2.2 |

2.2 |

| 脉动冲程Pulsating stroke |

mm |

0-50 |

0-50 |

0-30 |

0-20 |

脉动冲次

Pulsating frequency |

r/min |

0-400 |

0-400 |

0-300 |

0-300 |

供水压力

Water pressure |

MPa |

0.1-0.2 |

0.1-0.2 |

0.2-0.4 |

0.15-0.3 |

耗水量

Consumption of flush water |

m3/h |

0.75-1.5 |

1.5-3.0 |

10-20 |

30-50 |

| 外形尺寸 (长×宽×高) Dimension |

mm |

1800×1400×1320 |

2000×1360×1680 |

2700×2000×2400 |

3200×2340×2700 |

| 质 量 Weight |

t |

1.5 |

3 |

6 |

14 |

| 型号规格Model |

单位Uite |

CGSL

-1500 |

CGSL

-1750 |

CGSL

-2000 |

CGSL -2500 |

CGSL -3000 |

转环外径

Ring diameter |

mm |

1500 |

1750 |

2000 |

2500 |

3000 |

转环转速

Rotating speed

of Ring |

r/min |

2-4 |

2-4 |

2-4 |

2-4 |

2~4 |

给矿粒度

Ore-feeding size |

mm |

≤2 |

≤2 |

≤2 |

≤2 |

≤2 |

给矿浓度

Ore-feeding

concentration |

% |

10-40 |

10-40 |

10-40 |

10-40 |

10~40 |

矿浆通过能力

Slurry put

through |

m3/h |

50-100 |

75-150 |

100-200 |

200-400 |

350~650 |

| 干矿处理量Capacity |

t/h |

20-30 |

30-50 |

50-80 |

100-150 |

150~250 |

额定背景场强

Background Field |

T |

1.0 |

1.0 |

1.0 |

1.0 |

1.0 |

额定激磁电流

Energizing

current |

A |

1050 |

1400 |

1400 |

1700 |

1400 |

额定激磁电压

Energizing

Voltage |

V |

42 |

44 |

53 |

55 |

62 |

额定激磁功率

Energizing Power |

kw |

44 |

62 |

74 |

94 |

87 |

| 转环电动机功率Ring Power |

kw |

3 |

4 |

5.5 |

11 |

18.5 |

脉动电动机功率

Pulsating Power |

kw |

4 |

4 |

7.5 |

11 |

18.5 |

| 脉动冲程Pulsating stroke |

mm |

0-30 |

0-30 |

0-30 |

0-30 |

0~30 |

脉动冲次

Pulsating

frequency |

r/min |

0-300 |

0-300 |

0-300 |

0-300 |

0~300 |

| 供水压力Water pressure |

MPa |

0.2-0.4 |

0.2-0.4 |

0.2-0.4 |

0.2-0.4 |

0.2~0.4 |

耗水量

Consumption of

flush water |

m3/h |

60-100 |

80-150 |

100-200 |

200-400 |

350-530 |

| 外形尺寸(长×宽×高)

Dimension |

mm |

3600×2900

×3200 |

3900×3300

×3800 |

4200×3550

×4200 |

5800×5000

×5400 |

6600×5300

×6400 |

| 质

量Weight |

t |

20 |

35 |

50 |

105 |

175 |

五、规格型号和主要参数(CGSL中磁机)Specifications and Parameters (CGSL

VPMIMS)

| 型号规格Model |

单位Uite |

CGSL-1500 |

CGSL-1750 |

CGSL-2000 |

CGSL-2500 |

| 转环外径Ring diameter |

mm |

1500 |

1750 |

2000 |

2500 |

转环转速

Rotating speed of Ring |

r/min |

2~4 |

3~4 |

3~4 |

3~4 |

| 给矿粒度Ore-feeding size |

mm |

-1.2(30~100) |

-1.2(30~100) |

-1.2(30~100) |

-1.2(30~100) |

给矿浓度

Ore-feeding concentration |

% |

10~40 |

10~40 |

10~40 |

10~40 |

矿浆通过能力

Slurry put through |

m3/h |

75~150 |

75~150 |

120~200 |

180~450 |

| 干矿处理量Capacity |

t/h |

30~50 |

30~50 |

50~80 |

80~150 |

额定背景场强

Background Field |

T |

0.4 |

0.6 |

0.6 |

0.6 |

额定激磁电流

Energizing current |

A |

800 |

1150 |

1150 |

1150 |

额定激磁电压

Energizing Voltage |

V |

15 |

17 |

20 |

37 |

额定激磁功率

Energizing Power |

kw |

12 |

20 |

23 |

43 |

| 转环电动机功率Ring Power |

kw |

1.5 |

4 |

5.5 |

5.5 |

脉动电动机功率

Pulsating Power |

kw |

4 |

4 |

7.5 |

11 |

| 脉动冲程Pulsating stroke |

mm |

0~30 |

0~30 |

0~30 |

0~30 |

| 脉动冲次Pulsating frequency |

r/min |

0~300 |

0~300 |

0~300 |

0~300 |

| 供水压力Water pressure |

MPa |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

耗水量

Consumption of flush water |

m3/h |

60~90 |

80~120 |

100~150 |

200~300 |

冷却水水量

Cooling water consumption |

m3/h |

3~4 |

4~5 |

5~6 |

6~7 |

| 外形尺寸(长×宽×高)

Dimension |

mm |

3800×2600×3000 |

3900×3300×3530 |

4120×3640×4100 |

5800×380×5200 |

| 质量Weight |

t |

15 |

28 |

40 |

60 |

|