|

PH-2型卧式砂泵 type horizontal sand pump

一、概述

I. Overview

PH—2型泵系单级单吸离心式衬胶泵,可输送各类不含有尖角的圆体颗粒的矿浆。输送矿浆最大浓度不超过65%(重量计),温度不得超过60℃。专用于输送有腐蚀性矿浆。

Pump model PH-2, as a single stage single suction centrifugal rubber lined pump, can be used to convey various ore pulps with round particles without sharp angles, of which the concentration does not exceed 65% (in weight) and the temperature shall not exceed 60℃. This pump is particular ideal for conveyance of corrosive pulp.

根据用途不同,泵轴分别用优质碳素钢、镍铬钢制成,护套分别为耐磨橡胶、耐磨耐酸橡胶与钢板合制制而成,叶轮为铸钢制骨架,分别外衬耐磨橡胶、耐磨耐酸橡胶制成,泵的旋转方向,从传动方向看为逆时针旋转。

Depending on the purposes, pump spindle is made of quality carbon steel and nickel-chrome steel; the sheath is made of abrasive rubber, wear resistant and acid-resisting rubber and steel plate; impeller is provided with a steel frame externally lined with abrasive rubber and abrasion-proof and acid-resisting rubber. Viewed from the drive, the pump rotates counterclockwise.

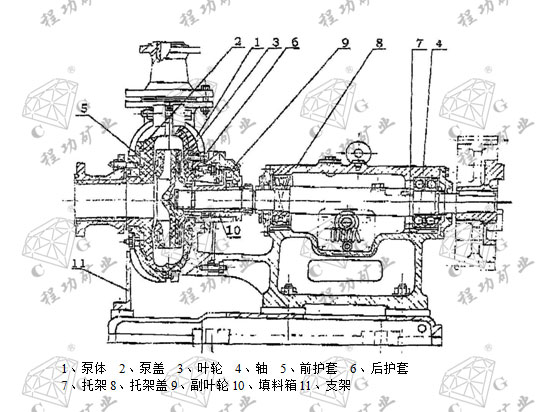

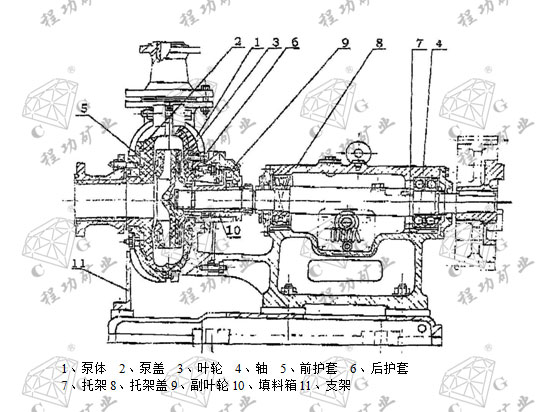

二、结构图

II. Structure Diagram

1. pump body 2. pump cover 3. impeller 4. spindle 5. front sheath 6. rear sheath.

7. pedestal 8. pedestal cap 9. auxiliary impeller 10. gland box 11. support

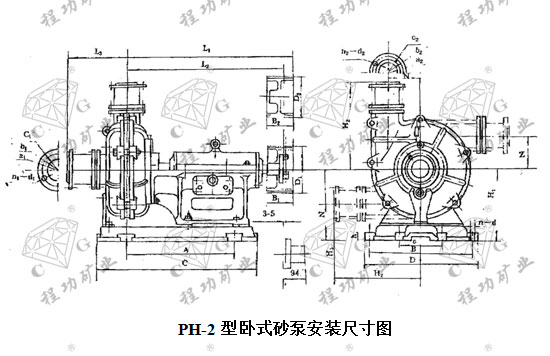

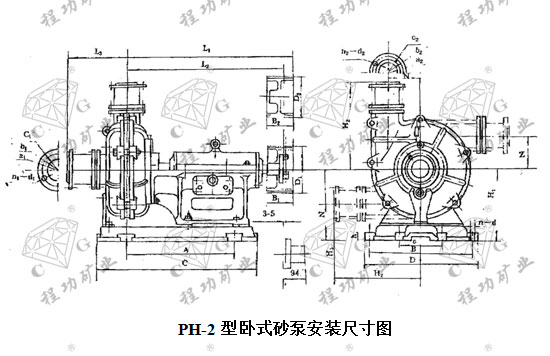

三、外形安装尺寸图

III. Overall Installation Dimension Diagram

Installation dimensions of horizontal sand pump model

四、外形安装尺寸表

砂泵型号

Sand

Pump

Model |

电机功率

Motor

Power |

A |

B |

C |

D |

E |

L1 |

L2 |

L3 |

H1 |

H2 |

H3 |

N |

h |

n-d |

e |

| PH-2 |

11kw

18.5kw |

600 |

550 |

919 |

610 |

|

890 |

860 |

260 |

400 |

443 |

243 |

157 |

40 |

4-Ф27 |

270 |

砂泵

型号

Pump Model |

三角皮带 V-belt |

皮带轮 Pulley |

进口法兰 Inlet flange |

出口法兰 Outlet flange |

| 型号 model |

根数Root number |

D1×B1 |

D2×B2 |

a1 |

b1 |

c1 |

n1-d1 |

a2 |

b2 |

c2 |

n2-d2 |

| PH-2 |

c |

4 |

Ф267×112 |

Ф334×112 |

Ф100 |

Ф180 |

Ф215 |

4-Ф18 |

Ф50 |

Ф130 |

Ф160 |

4-Ф19 |

五、工作性能表

| 型 号model |

流量 Flow |

扬 程 Head |

转 速 Speed |

允许配带最大功率 Equipped with the maximum power allowed |

效率 Efficiency |

叶轮Impeller |

泵重Pump weight |

| Q |

H |

N |

轴功率 |

电机功率 |

|

㎜ |

Kg |

| m3/h |

L/S |

m |

r/min |

kw |

% |

195 |

127 |

| PH-2 |

12 |

3.33 |

14 |

1430 |

1.2 |

3 |

38 |

| 15 |

4.17 |

13 |

1.3 |

40 |

| 18 |

5 |

11.5 |

1.4 |

40 |

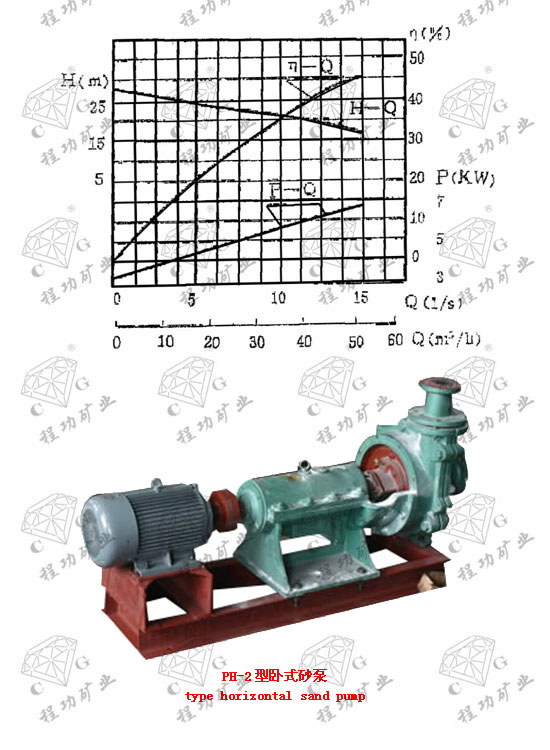

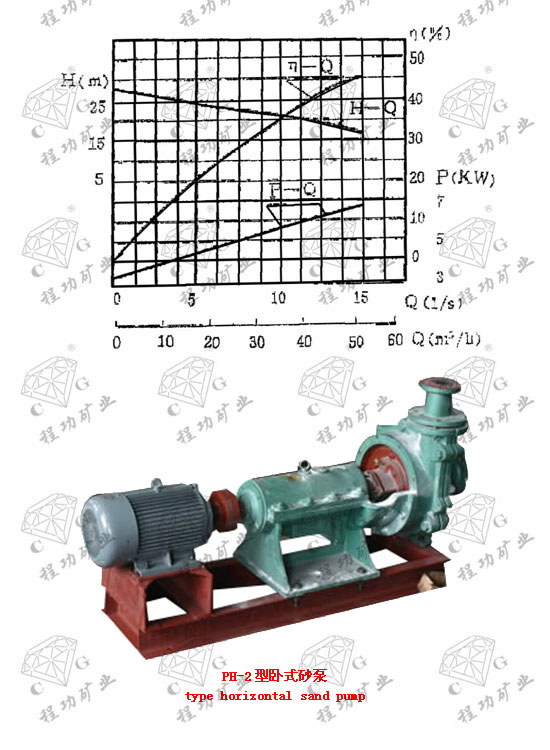

六、工作性能图

|