|

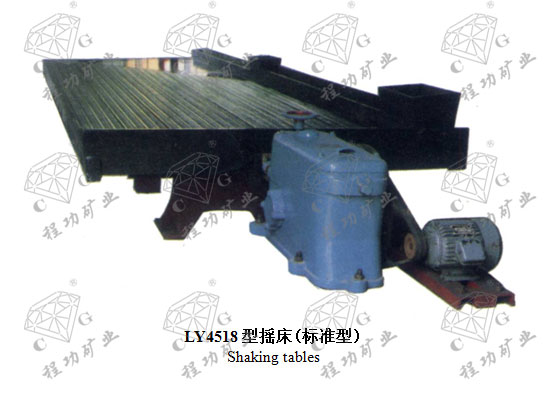

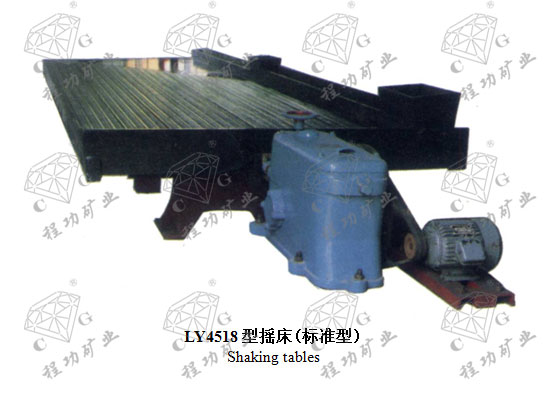

LY型摇床Shaking table

一、用途

适用于细粒和微细粒稀有金属、黑色金属、有色金属、贵重金属等矿石和煤的选别。它不仅可以作为一个独立的选矿作业,亦可以与跳汰机、螺旋选矿机、离心选矿机等或其他选矿方法配合使用。本产品由原地矿部唯一指定企业生产,执行行业标准。

本设备依据入选矿物比重差和在往复不对称运动并呈倾斜的床面横向水流中的分层参数进行选别。具有不同比重矿物在床面上分带明显,精矿质量高、操作和调节方便等特点。

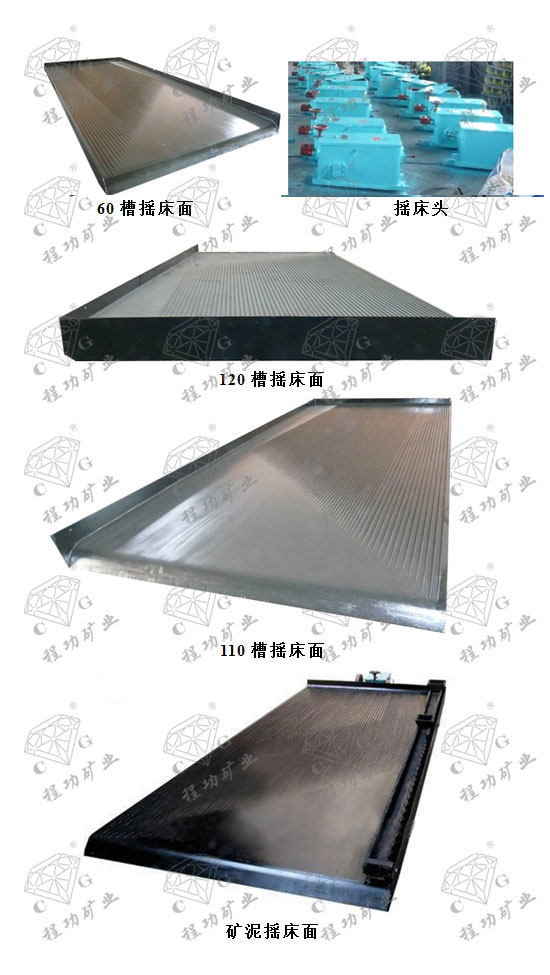

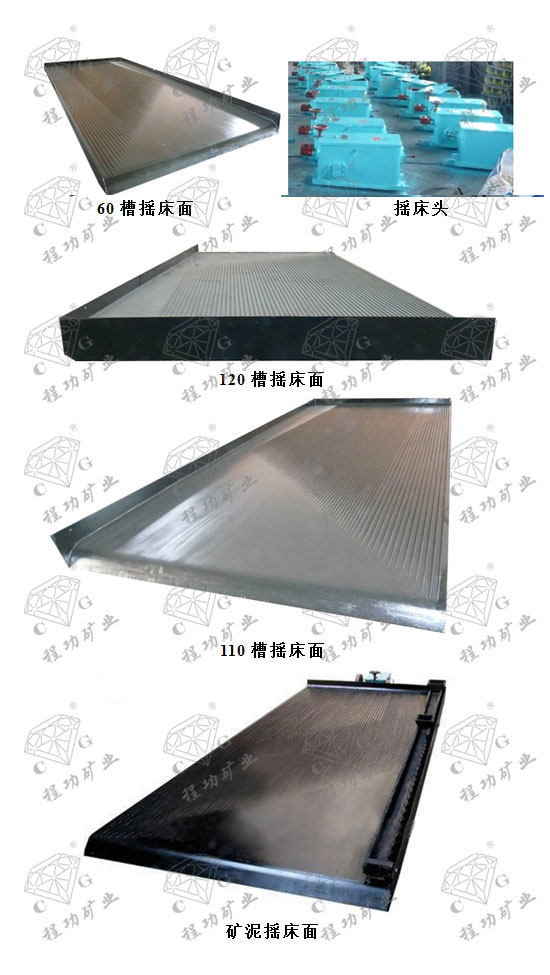

摇床面结构有矿砂、矿泥之分,材质分别有玻璃钢或铝合金。

It is applicable for

separations of fine-grained and micro-grained rare metal, ferrous and non-ferrous

metal, precious metal , coal and other minerals. It can carry out ore

concentration operation independently and also can operate in conjunction with

jig, screw separator, centrifugal separator and other equipment. The product is

made by the only manufacturer designated by the former Ministry of Geology and

Mineral Resources, in compliance with the Industrial standards.

LY Shaking Table is to make

separations based on the difference of specific gravity of feed materials,

reciprocating asymmetrical movement and the stratification performance of the

inclined table surface in the lateral water flow with obvious zone of the

minerals with different specific gravities on the table, high quality of

concentrates produced, convenient operation and adjustment and other features.

The table surface is

constructed of ore sand or slime and is made up of glass fibre reinforced

plastic or aluminum alloy.

LY型玻璃钢床面摇床是有效重选设备。可供大、中、小型选厂进行粗选、精选、扫选等不同作业,适用于分选细粒和微粒的有色、黑色、稀贵金属、黄金及非金属矿物。该摇床分矿砂床和矿泥床,矿砂床适用于分选较粗的矿物,矿泥床适用于分选较细的矿物。

LY glass steel shaking tables

are effective gravity separation equipment which can be used for different

operation such as rough selection, elaborate selection and scavenging for

large, medium and small-sized factories and applies to the sorting of nonferrous

metal, ferrous metal, rare and precious metal, gold and nonmetallic ores of

fine grains. Such shaking tables are divided into ore sand tables and ore slime

tables. Ore

sand tables apply to the sorting of coarse ores and ore slime tables apply to

the sorting of fine ores.

二、主要技术参数

| 型号规格 Model |

床面尺寸 |

冲程 Stroke |

冲次 Times of stroke |

给料粒度

Feed size |

耗水量

Water consumption |

处理能力 Capacity |

功率 Power |

质量 Weight |

| mm |

mm |

1/min |

mm |

t/min |

t/h |

kw |

t |

| LY 4518 矿砂 |

4500×1850

×1560 |

10-30 |

240-420 |

0.074 |

0.5-1.5 |

2 |

1.5 |

1.35 |

| LY 4518 矿泥 |

4500×1850

×1560 |

10-30 |

240-420 |

0.074 |

0.4-0.7 |

1.8 |

1.5 |

1.35 |

| LY 4518 双波 |

4500×1850

×1560 |

10-30 |

240-420 |

0.1 |

0.5-1.5 |

1.8 |

1.1 |

1.1 |

| LY 3013 矿泥 |

3000×1620

×1100 |

6-30 |

210-320 |

0.074 |

0.3-1.5 |

1.5 |

1.1 |

0.7 |

| LY 2110 矿泥 |

2100×1050

×850 |

12-28 |

250-450 |

0.074 |

0.3-1 |

0.3-0.8 |

0.75 |

0.5 |

| LY 1150 矿泥 |

1100×500

×430 |

9-17 |

280-460 |

0.074 |

0.1-0.5 |

0.05-0.2 |

0.55 |

0.15 |

三、工作原理和主要结构

II. Structure and Working Principle

本机的工作原理是利用被分选矿物的比重差、床面的往复差运动、横向斜面水流及床条(或刻槽)诸因素的综合作用,使矿物在床面上松散分层,形式扇形分带而产出不同产品.

The working principle of this machine is to use the combined

action of the specific gravity difference of sorted minerals, alternating

movement of bed surface, and transverse oblique water flow and riffle (or notch

groove), to allow loose layering of ores on the bed surface and fan-shaped

zoning. Then different products can be produced.

本机由摇床头、床面、支承及调坡机构三大部份组

This machine is composed of three parts, i.e. head of shaking

table, surface of shaking table, as well as bearing and adjusting gradient.

1、摇床头:为一偏心连杆式机构,电机带动偏心轴旋转及连杆作上下运动。当连杆向下推动肘板压缩弹簧时,使拉杆带动床面向床头方向运动,当连杆向上时,利用弹簧张力,推动床面向相反主向运动。连续起来,则将偏心轴的旋转运动变为床面水平往复差速运动。

1. Head of shaking table: This is eccentric connecting-rod type

mechanism. The motor drives the eccentric shafts to rotate and the connecting

rod to move up and down. When the connecting rod pushes down the toggle plate

compression spring, the pull rod drives the table surface to move in the

direction of table head. When the connecting rod pushes it upward, it, through

the spring tension, drives the table surface to move in the opposite direction.

When they are linked, the rotating motion of eccentric shaft is changed into

horizontal alternating differential motion of table surface.

2、床面:主要由摇动顶板、钢骨架、玻璃钢及耐磨表面、给水槽、给矿槽、牵引拉杆等组成。床面采用钢骨架玻璃钢复合结构。即在钢骨架上表糊玻璃钢,形式一个坚实的玻璃钢板面,其上再用耐磨材料制成工作表面和床条(或刻槽)。

2. Table surface: It is mainly composed of vibrating roof, steel

skeleton, glass fiber reinforced plastics and wear-proof surface, feed water

tank, feed chute, and draw bar. The table surface adopts steel skeleton FRP

composite structure. That is, glass fiber reinforced plastics are pasted on

steel skeleton to form a solid glassfiber reinforced plastic surface. Its above

uses abrasion-proof materials to make surface and riffle (notch groove).

3、支承及调坡机构

3. Bearing and Adjusting Gradient Mechanism

主要由摇动撑板、调节座板、鞍形座和调节丝杆等部份组成。摇动撑板使床面在垂直平面内作弧线起伏的前后往复运动。摇动撑板和摇动盒用夹持槽钢固定在调节座扳上,当用手轮调节丝杆使用调节座板在鞍形座上转动时,即可调节床面横向坡度。

The bearing and adjusting gradient mechanism is mainly composed of

shaking support plate, adjusting seat board, saddle seat, and adjusting screw

rod. The shaking support plate enables the table surface to make arc forward

and backward alternating movement on vertical plane. The shaking support plate

and shaking box are fixed on the adjusting seat board with gripping channel

steel. When hand wheel regulating screw rod is used to get the adjusting seat

board to rotate on the saddle seat, the Transverse gradient of table surface

can be adjusted.

|