|

|

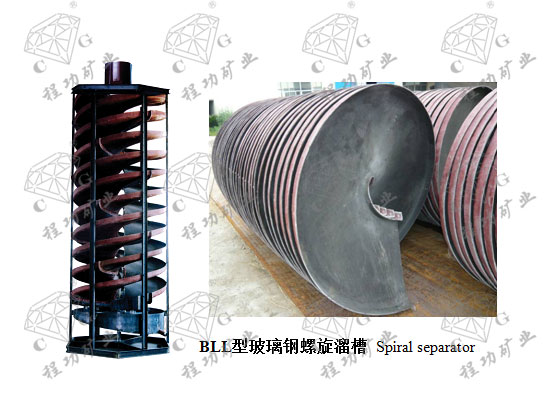

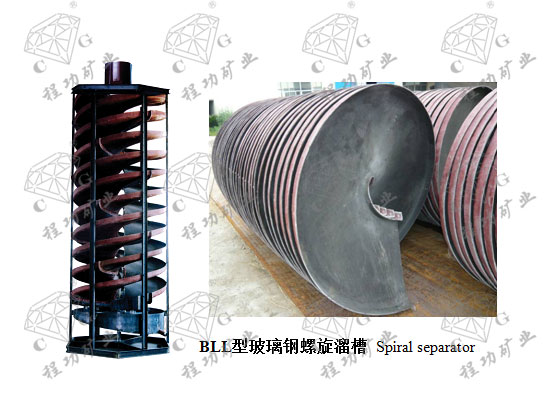

BLL型玻璃钢螺旋溜槽 Glass fibre reinforced plastic spiral chute

BLL型玻璃钢螺旋溜槽用于选别细粒(包括细微粒度)的金属矿物,如铁矿、钛铁矿、铬铁矿、硫铁矿、钨锡矿、铌钽矿、砂金矿、海滨的独居石、金红石、锆英石及有足够比重差的其它金属和非金属矿物选别。本产品由原地矿部唯一指定企业生产,执行行业标准。

螺旋溜槽是根据有用矿物与脉石矿物在比重、粒度、形状上的差异,在螺旋的斜面产生矿浆动感的离心流膜,在重力和离心力的综合力场中,利用不同颗粒所受重力、水动压力和摩擦力,实现有用矿物与脉石分选的。螺旋槽中的水动除作向下的螺旋运动外,还作横向的循环流动。上层水流流速快,产生较大惯性离心力,甩向槽的外缘。与槽底相邻的下层水流回转速度慢,离心力小,在重力作用下从外缘流向内缘,产生二次回流。矿浆中的重矿粒沉降快,沿收敛的螺旋线逐渐移向内缘,最后以精矿形式产生。轻矿物沉降慢,处于矿流表层,流速快,离心力大,在横向环流作用下,沿扩渐的螺旋线逐渐移向外缘,最后以尾矿形式产出。

Laboratory BLL Glass Fibre Reinforced Plastic

Spiral Chute is applicable for separation of fine-grained ( including

micro-grained ) metallic minerals such as iron, ilmenite ,chromite,

tungsten-tin ore, niobium-tantalum ore, gold placer, seashore monazite, rutile and zircon as well as other

metallic and non-metallic minerals with adequate difference of specific

gravity. The product is made by the only manufacturer designated by the former

Ministry of Geology and Mineral Resources, in compliance with the Industrial

standards.

Spiral Chute is to make separations of useful

minerals from gangues by use of the different particles subject to gravity,

hydraulic pressure and friction in the multi-force field through dynamic

centrifugal flowing membrane of slurry produced on the inclined surface of

spiral based on the differences of useful mineral and gangue in specific

gravity, particle size and shape. Water in the spiral chute runs downward

spiral movement and also flows in circulation transversely. Water in the upper

layer run fast, generating centrifugal force with large inertia to toss toward

the outer edge of the chute. Back-flow of water in the lower layer adjacent to

the chute bootom runs slowly with small centrifugal force and flows from the

outer edge to the inner edge with the action of gravity, generating secondary

back-flow. Particles of heavy minerals in slurry settle rapidly and gradually

moves toward the inner edge along the converged helix prior to finally being

produced as concentrate. Light minerals settle slowly and flow fast in the

surface layer of ore flow with large centrifugal force and gradually move

toward the outer edge along the expanding helix before finally being produced

as tailings.

| 型号

规格 Model |

外径

Diameter |

螺距

Picth |

螺旋头数 |

给矿 粒度

Feed size |

给矿

浓度 |

处理量

Capacity |

外形尺寸

Overall dimensions |

重量

Weight |

| mm |

mm |

个 |

mm |

% |

t/h |

mm |

kg |

| BLL600×450 |

600 |

450 |

3,2 |

≤0.2 |

30-60 |

1.0-1.4 |

700×700 ×3000 |

120 |

| BLL900×540 |

900 |

540 |

4,3 |

≤0.3 |

30-60 |

2-3 |

1010×1060 ×4000 |

400 |

| BLL900×675 |

900 |

675 |

4,3 |

≤0.3 |

30-60 |

2.5-3.5 |

1010×1060 ×4650 |

450 |

| BLL 1200×540 |

1200 |

540 |

3,2 |

≤0.3 |

30-60 |

3-0.4 |

1360×1360 ×4330 |

600 |

| BLL 1200×720 |

1200 |

720 |

4,3 |

≤0.3 |

30-60 |

4-6 |

1360×1360 ×5230 |

650 |

| BLL 1200×900 |

1200 |

900 |

4,3 |

≤0.3 |

30-60 |

5-7 |

1360×1360 ×6130 |

700 |

| BLL 1500×675 |

1500 |

675 |

4 |

≤0.8 |

30-60 |

8 |

1800×1800 ×6130 |

800 |

| BLL 1500×900 |

1500 |

900 |

4 |

≤0.8 |

30-60 |

8.5 |

1800×1800 ×6130 |

850 |

| BLL 2000×900 |

2000 |

900 |

3 |

≤4 |

30-60 |

5-35 |

2300×2300 ×6130 |

1000 |

| BLL 2000×1200 |

2000 |

1200 |

3 |

4-0.04 |

30-60 |

15-40 |

2300×2300 ×6500 |

1100 |

| |