|

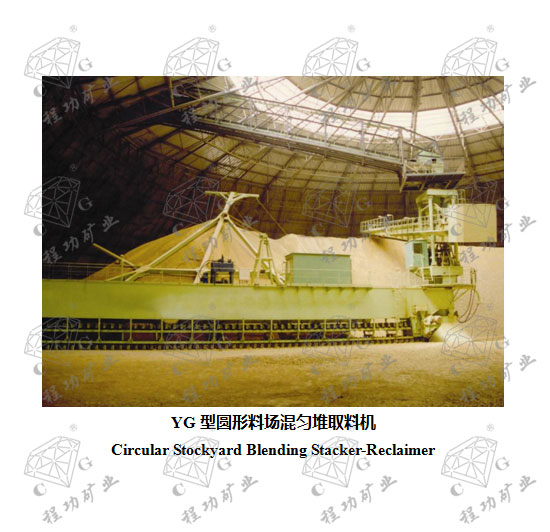

YG型圆形料场混匀堆取料机 Circular

Stockyard Blending Stacker-Reclaimer

北方重工沈矿集团有限责任公司从八十年代中期开始研制堆取料机产品,通过与世界各国的先进专业制造厂家广泛的技术交流,特别是同德国PWH和MVT等公司卓有成效的合作,使该公司堆取料机设计及制造水平迅速提高。现已形成圆形料场混匀堆取料机、长形料场混匀堆取料机、臂式斗轮堆取料机、顶堆侧取圆形料场堆取料机等系列产品,形成了自行设计、制造、安装、调试一条龙服务体系。现已有近1500台套堆取料机应用于建材、煤炭、冶金、电力港口等行业。

Northern Heavy Industry Shenyang Mining

Machinery (Group) Co., Ltd began to develop stack-reclaimers during the mid-eighties.

Thanks to its extensive technological exchange with advanced and professional

manufacturers all over the world as well as effective cooperation with PWH,

MVT, etc in Germany ,

this company has been able to achieve rapid improvement of the design and

manufacture level of stacker-reclaimers. Now it has already developed a series

of products such as circular stockyard blending stacker-reclaimers, rectangular

stockyard blending stacker-reclaimers, boom-type bucket wheel stacker

reclaimer, and top-stacking side-drawing circular stockyard stacker-reclaimer,

as well as formed a service system from self design, manufacture, and

installation to debugging. At present, there are nearly 1,500 sets of

stacker-reclaimers applied in industries such as building material, coal,

metallurgy, power and port.

工作原理

Work Principle

圆形料场混匀堆取料机是一种理想的散状物料均化设备,适用于大型水泥厂的原料预均化,也广泛应用于煤炭、电力、冶金、化工、港口等行业需要对散状物料进行存贮,均化的堆场。

Circular stockyard blending

stacker-reclaimers are a kind of ideal bulk material blending equipment which

apply to preblending of raw materials in large cement plants. Besides, they are

widely used in stockyards where storage and blending of bulk materials are

needed in industries such as coal, power, metallurgy, chemical and port.

圆形料场混匀堆取料机主要由可回转的悬臂堆料机、中柱、桥式刮板(刮斗)取料机、电控系统等组成。中柱安装在圆形料场的中心,中柱上部安装有可回转的悬臂堆料机,悬臂堆料机可绕中柱360°回转并在变幅油缸的驱动下进行变幅,通过回转机构和变幅机构的合成运动完成堆料作业。取料机是一台绕中往回转的桥式刮板(刮斗)取料机,通过取料机桥梁上往复运动的料耙,将料堆物料逐层松动并拨落至料堆底部,再由刮板(刮斗)取料系统将已被均化的物料输送至中柱下面的出料漏斗,通过漏斗将物料卸至地下的带式输送机运出堆场。

Circular stockyard blending

stacker-reclaimer is mainly composed of rotatable boom stacker, central pillar,

bridge-type scraper (scraping bucket) reclaimer., and electric control system.

The central pillar is installed in the center of circular stockyard. The top of

the central pillar is equipped with rotatable boom stacker, which can rotate 360°

around the central pillar, change its amplitude when driven by the derricking

cylinder, and finish material stacking through the synthesis movement of

slewing mechanism and luffing mechanism. The reclaimer is a bridge-type scraper

(scraping bucket) reclaimer which rotates around the central pillar. It loosens

the stacking materials in the material pile layer by layer and get them to the

bottom of the material pile through the material rake which moves back and

force on the reclaimer bridge. Then the scraper (scraping bucket) reclaiming

system transports the blended materials to the discharging hopper below the

central pillar through which the materials are discharged to the belt conveyor

and then conveyed out of the stockyard.

结构特点与优势:

Structural

Feature and Advantage

该设备占地面积小,可连续进行堆、取料作业,全自动控制,是煤炭、水泥原料等散状物料理想的均化设备。

Such equipment occupies a small

area. In addition, it can stack and reclaim materials continuously and is fully

automatic. Thus is is an ideal kind of blending equipment for bulk materials

such as coal and cement raw materials.

该公司设计制造的圆形料场混匀堆取料机,其料场最大直径为中φ120m。

For the circular stockyard blending

stacker-reclaimer designed and manufactured by our company, the maximum

diameter of its stockyard is φ120m.

圆形料场混匀堆取料机主要性能参数

| 物料特性 |

名称 |

煤,矿石等 |

供电方式 |

安全滑触线,电缆卷筒 |

| 堆积密度t/m3 |

0.62~2.5 t/m3 |

| 粒度(mm) |

0~300 |

| 含水量 |

-10% |

| 安息角° |

27°~50° |

通讯方式 |

电缆卷筒,滑触线,无线通讯 |

| 主要指标 |

取料/堆料(t/h) |

500-4000/

500-2000 |

| 轨道半径(m) |

φ60-φ120 |

圆形料场混匀堆取料机型号规格表

| 型号 |

名称 |

堆料机 |

取料机 |

适用物料 |

贮存能力m3 |

控制方式 |

| 堆料能力t/h |

带宽mm |

取料能力 t/h |

刮板宽/链速 mm/m/s |

| YG60 |

圆料场桥式刮板堆取料机 |

500-800 |

~650-1000 |

40-200 |

~1800/0.4 |

原煤、分级煤、石灰石及其它散状物料 |

15000 |

自动控制手动控制 |

| YG80 |

500-1000 |

~650-1200 |

40-400 |

~1800/0.5 |

34000 |

| YG90 |

500-1200 |

~800-1200 |

250-500 |

~1800/0.6 |

52000 |

| YQL78 |

500-800 |

~650-1200 |

1000 |

~2000/0.7 |

30000 |

| YG100 |

1000-2000 |

~800-1400 |

800-1200 |

~2000/0.7 |

75000 |

| YG110 |

1000-2500 |

~800-1400 |

1000-1200 |

~2000/0.7 |

86000 |

| YG120 |

1500-3000 |

~800-1600 |

1200-1500 |

~2500/0.7 |

95000 |

|