|

|

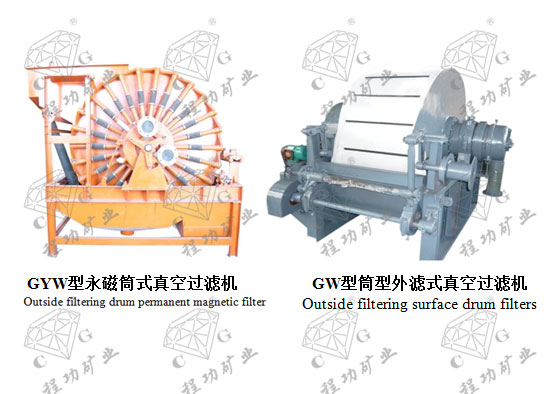

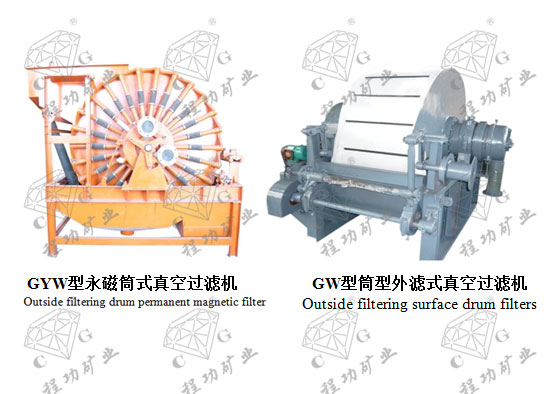

GYW、GW型外滤筒式真空过滤机

Outside

filtering drum permanent magnetic filter

国家行业标准JB/T2443

外滤筒式真空过滤机广泛用于选矿、冶金、化工造纸等部门,对经浮选后的有色金属(铜、锌、铅、镍……)和非金属(硫、磷、滑石、萤石……)精矿、精煤等进行脱水,也可用于对不易沉淀的悬浮液进行固液分离。

Out side-drum vacuum filter is widely used in ore-processing,

metallurgical industry, chemical plant, paper industry and etc, for dewatering

floatation concentrates of non ferrous metals (such as copper, zinc, lead,

nickel and etc,) and concentrates of non metal (such as sulphur, phosphorus,

talcum, fluorite, coal and etc,) and can also be used for separating liquid and

soild in suspensoids which are not easy to be setted down.

结构:主要由转鼓、槽子、分配头、搅拌器、传动装置等主要部件组成。

Structure: This kind of

equipment is mainly composed of drum, trough, distribution head, blender, and

transmission device.

工作原理:过滤机操作时矿浆送入溶槽内,这时,槽内的矿浆由于受搅拌器搅拌而得保持悬浮状态,圆盘转动时,由于真空过滤机内部的真空,固体物料从矿浆内被吸到此时沉没在盛有矿浆的槽里的这部份转鼓外圆表面上。在该过滤机的表面处于真空下时,滤渣形成带和脱水带一直保持着。这时,粘挂在上面的物料开始被吸干,在转鼓的继续转动下,出现滤渣刮取带,在这里,由转鼓内部的真空变为压缩空气,将滤渣吹下和将滤布滤孔吹通。为了能将过滤表面上的滤渣取下,要装上一种特殊的刮刀。在转鼓表面重新浸入矿浆前,过滤机表面又受真空作用。

Working

Principle: During the operation of the filter, the slurry is fed into the

trough. At this time, the slurry in the trough remains suspended as the result

of the stirring of the blender. When the disc rotates, due to the vacuum in the

vacuum filter, the solid materials are sucked from the slurry to the surface of

the excircle of this drum submerged in the tank containing slurry. When the

surface of the filter is exposed to vacuum, filter residual formation belt and

dewatering belt are always retained. At this time, materials sticking to it

begin to be sucked dry. When the drum continues to rotate, filter residual

scraping belt appears. Here the vacuum inside the drum changes into compressed

air. It blows down the filter residual and blow off through the filtration hole

of filter cloth. To remove the filter residual on the filtering surface, a kind

of special scraper shall be installed. Before slurry is reinfused to the

surface of the drum, the surface of the filter is again affected by vacuum.

| 型号规格Model |

过滤面积Filtering Area |

筒体尺寸Drum Dimens |

筒体转速Drum Speed |

筒表磁感强度Drum Surface Intensity |

滤饼水分Cake Moisture |

产量Capa. |

功率Power |

质量Weigh |

| m2 |

mm |

r/min |

MT |

(%) |

t/h |

kw |

t |

GYW永磁筒式过滤机 Outside filtering drum permanent magnetic filter

适用磁性矿物脱水,产量是其他过滤机的3倍。 |

| GYW3 |

3 |

Φ1.6×0.7 |

0.5-2 |

82 |

8-10 |

6-9 |

1.5 |

3.27 |

| GYW5 |

5 |

Φ2×0.9 |

0.5-2 |

82 |

8-10 |

14-18 |

1.5 |

3.94 |

| GYW8 |

8 |

Φ2×1.4 |

0.5-2 |

82 |

8-10 |

22-43 |

1.5 |

4.76 |

| GYW12 |

12 |

Φ2×2 |

0.5-2 |

87 |

8-10 |

33-65 |

2.2 |

5.42 |

| GYW20 |

20 |

Φ2.55×2.65 |

0.5-2 |

87 |

8-10 |

50-100 |

4 |

6.53 |

| GW型筒型外滤式真空过滤机 Outside filtering surface drum filters |

| GW3 |

3 |

Φ1.6×0.7 |

0.5-2 |

搅拌次数 |

10-17 |

1.1 |

1.5/0.8 |

2.36 |

| GW5 |

5 |

Φ2×0.9 |

0.1-2 |

23次/min |

10-17 |

2 |

1.5/0.8 |

3.76 |

| GW8 |

8 |

Φ2×1.4 |

0.1-2 |

23 |

10-17 |

3.2 |

1.5/0.8 |

4.88 |

| GW12 |

12 |

Φ2×2 |

0.1-2 |

23 |

10-17 |

4.8 |

1.5/0.75 |

5.6 |

| GW20 |

20 |

Φ2.5×2.65 |

0.14-0.54 |

25/45 |

10-17 |

3-8 |

3/2.2 |

10.6 |

| GW30 |

30 |

Φ3.35×3 |

0.11-0.56 |

25/45 |

10-17 |

4.5-12 |

3.3/3 |

17.2 |

| GW40 |

40 |

Φ3.35×4 |

0.11-0.56 |

25/45 |

10-17 |

6-16 |

4.5/3 |

19.5 |

| GW50 |

50 |

Φ3.35×5 |

0.11-0.56 |

25/45 |

10-17 |

7.5-20 |

5/4 |

21 |

| |