|

2CTB、2CTN、2CTS型双筒湿式永磁筒式磁选机

Wet

permanent magnetic double drum separator

国家行业标准JB/T7895

一、适用范围

该机主要用于弱磁场湿式选别或除去细颗粒的强磁性矿物,广泛用于选矿,洗煤和化工等行业,如:回收重介质选矿中的磁性重介质如重剂;铁选矿中低浓渡矿浆的浓缩和磁铁矿物的富集;处理强磁选机的给矿,清除其中的磁性或较弱磁性矿物及其连生体,防止磁介质堵塞。

在湿式磁选作业中,若要求获得纯净的磁性矿物,通常选用顺流型磁选机。此时,磁性矿物的回收率有可能会降低;若要求最大限度地回收磁性矿物,则选用逆流型磁选机。此时,磁性矿的品位有可能会降低。当要兼顾磁性矿物的品位和回收率时,以选用半逆流磁选机较为适宜。

二、工作原理

其原理是当矿浆进入磁场时,其中强磁性矿物被吸附在圆表面,弱磁性和非磁性矿物被甩掉排出,而吸咐在圆筒表面上的强磁性矿物随圆筒旋转而被带出磁场区,用冲洗水冲入清矿槽中,完成分选作业。

三、产品特点

1、介质回收率高达99%;

2、采用高能稀土永磁材料;

3、磁系结构设计合理、稳固、耐用、密封良好;

4、整体设计成模块式结构、易于对中定位安装、易于维修;

5、筒体两端采用耐磨铝制法兰;

6、箱体设计结构合理,大颗粒清理方便自如,箱体强度大、钢度好;

7、传动系统简单耐用,易于拆装,易于调整:

8、调整方法:拧调磁螺丝让磁场离卸料板3公分左右即可。

四、槽体分类

同一圆筒可配三种槽体,即顺水槽(CTS)、逆水槽(CTN)、半逆水槽(CTB),分别适用于不同选别粒度及不同选别工艺的要求。

顺水槽适用于矿石粒度为6-0mm的粗选和精选;

逆水槽适用于矿石粒度为0.6-0mm的粗选和精选,以及选煤工业中重介质回质;

半逆流槽适用于矿石粒度为1-0mm的粗选和精选,尤其适用于粒度为0.15-0矿物的精选。

I. Applicable Scope

This type of equipment is mainly used to select wet weak magnetic

field and remove the strongly magnetic minerals of fine grains. They are widely

used in mineral processing industry, coal washing industry, chemical industry,

etc, e.g. recycle heavy formulas such as magnetic heavy media during heavy

media separation, concentrate low-concentration slurry in iron ore and gather

magnetic steel minerals, treat ore feeding from high-intensity magnetic

separators, remove magnetic or weakly magnetic ores and coenobium, as well as

prevent blockage of magnetic media.

During wet magnetic separation, to get pure magnetic minerals,

downstream magnetic separators are usually selected. In such case, the recovery

ratio of magnetic minerals might be reduced. If the magnetic minerals are

required to be recycled to the largest extent, counter-current magnetic

separators shall be selected. In this case, the grade of magnetic minerals

might be reduced. If both the grade and recovery rate of magnetic minerals

shall be taken into account, semi-countercurrent magnetic separators might be

more appropriate.

II. Working Principle

When slurry goes into the magnetic field, the strongly magnetic

minerals are absored on the surface of the circle; the weakly magnetic minerals

and non-magnetic minerals are thrown away and discharged; the strongly magnetic

minerals absorbed on the surface of cylinder are taken out of the magnetic

field as the cylinder rotates. Pour the flushing water to the ore cleaning tank

to finish separation.

III. Product Feature

1. Media recovery ratio is as high as 99%;

2. High energy rare-earth permanent-magnet materials are adopted;

3. The magnetic structure is reasonably designed, stable, durable,

and well sealed;

4. The overall design is of module structure, and is easy for centering

installation and maintenance.

5. Wear-resistant aluminum flanges are adopted at the two ends of

cylinder;

6. The structure of box is reasonably designed; the large

particles can be easily removed; and the box is strong.

7. The transmission system is simply structured, durable and easy

for dismounting and adjustment.

8. Adjustment method: Adjust the magnetic screw to get the

magnetic field around 3 cm

away from the stripper plate.

IV. Classification of Tank

The same one cylinder can be equipped with three types of tanks

i.e. downstream tank (CTS), counter-current tank (CTN), and semi-countercurrent

tank (CTB) which are respectively applicable to different participle size and

different technology.

Downstream tanks apply to rough selection and elaborate selection

of ores with particle size of 6-0mm.

Counter-current tanks apply to rough selection and elaborate

selection of ores with particle size of 0.6-0mm,

as well as recycle of heavy media in coal preparation industry.

Semi-countercurrent tanks apply to rough selection and elaborate

selection of ores with particle size of 1-0mm,

especially to elaborate selection of ores with particle size of 0.15-0mm.

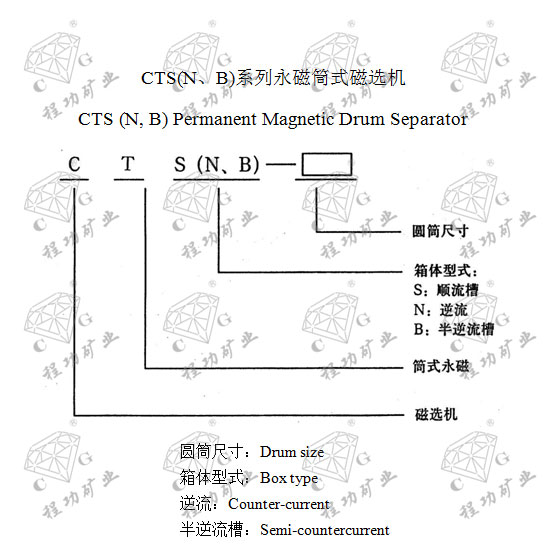

五、型号说明

V. Model Description

型号规格

Model |

筒径

Dia. |

筒长

Drum

length |

转速

Speed |

磁感强度

Magnetic

inductino

density |

分选粒度

Partide

sorting |

处理能力

Capacity |

功率

Power |

重量

weight |

| mm |

mm |

r/min |

mT |

mm |

m³/h |

kw |

t |

2CTB型双筒湿式半逆流永磁转筒磁选机

Wet permanent

magnetic double drum separator for semi-backflow tan |

| 2CTB-1018 |

1050 |

1800 |

21 |

300 |

0-1 |

100-280 |

5.5×2 |

8.81 |

| 2CTB-1021 |

1050 |

2100 |

21 |

300 |

0-1 |

130-310 |

5.5×2 |

9.45 |

| 2CTB-1024 |

1050 |

2400 |

21 |

300 |

0-1 |

160-340 |

5.5×2 |

9.98 |

| 2CTB-1027 |

1050 |

2700 |

21 |

300 |

0-1 |

190-370 |

7.5×2 |

10.55 |

| 2CTB-1030 |

1050 |

3000 |

21 |

300 |

0-1 |

220-400 |

7.5×2 |

11.17 |

| 2CTB-1033 |

1050 |

3300 |

21 |

300 |

0-1 |

250-430 |

7.5×2 |

12.40 |

| 2CTB-1218 |

1200 |

1800 |

19 |

300 |

0-1 |

140-330 |

5.5×2 |

10.1 |

| 2CTB-1221 |

1200 |

2100 |

19 |

300 |

0-1 |

170-360 |

7.5×2 |

10.8 |

| 2CTB-1224 |

1200 |

2400 |

19 |

300 |

0-1 |

200-390 |

7.5×2 |

11.4 |

| 2CTB-1227 |

1200 |

2700 |

19 |

300 |

0-1 |

230-420 |

7.5×2 |

12.1 |

| 2CTB-1230 |

1200 |

3000 |

19 |

300 |

0-1 |

260-450 |

7.5×2 |

12.76 |

2CTN型双筒湿式逆流永磁转筒磁选机

Wet permanent

magnetic double drum separator backflow |

| 2CTN-1018 |

1050 |

1800 |

21 |

300 |

0-0.6 |

100-280 |

5.5×2 |

8.81 |

| 2CTN-1021 |

1050 |

2100 |

21 |

300 |

0-0.6 |

130-310 |

5.5×2 |

9.45 |

| 2CTN-1024 |

1050 |

2400 |

21 |

300 |

0-0.6 |

160-340 |

5.5×2 |

9.98 |

| 2CTN-1027 |

1050 |

2700 |

21 |

300 |

0-0.6 |

190-370 |

7.5×2 |

10.55 |

| 2CTN-1030 |

1050 |

3000 |

21 |

300 |

0-0.6 |

220-400 |

7.5×2 |

11.17 |

| 2CTN-1033 |

1050 |

3300 |

21 |

300 |

0-0.6 |

250-430 |

7.5×2 |

12.40 |

| 2CTN-1218 |

1200 |

1800 |

19 |

300 |

0-0.6 |

140-330 |

5.5×2 |

10.1 |

| 2CTN-1221 |

1200 |

2100 |

19 |

300 |

0-0.6 |

170-360 |

7.5×2 |

10.8 |

| 2CTN-1224 |

1200 |

2400 |

19 |

300 |

0-0.6 |

200-390 |

7.5×2 |

11.4 |

| 2CTN-1227 |

1200 |

2700 |

19 |

300 |

0-0.6 |

230-420 |

7.5×2 |

12.1 |

2CTS型双筒湿式顺流永磁转筒磁选机

Magnetic wet double

drum separator for concurrent flow |

| 2CTS-1018 |

1050 |

1800 |

21 |

300 |

0-6 |

100-280 |

5.5×2 |

8.81 |

| 2CTS-1021 |

1050 |

2100 |

21 |

300 |

0-6 |

130-310 |

5.5×2 |

9.45 |

| 2CTS-1024 |

1050 |

2400 |

21 |

300 |

0-6 |

160-340 |

5.5×2 |

9.98 |

| 2CTS-1027 |

1050 |

2700 |

21 |

300 |

0-6 |

190-370 |

7.5×2 |

10.55 |

| 2CTS-1030 |

1050 |

3000 |

21 |

300 |

0-6 |

220-400 |

7.5×2 |

11.17 |

| 2CTS-1033 |

1050 |

3300 |

21 |

300 |

0-6 |

250-430 |

7.5×2 |

12.40 |

| 2CTS-1218 |

1200 |

1800 |

19 |

300 |

0-6 |

140-330 |

5.5×2 |

10.1 |

| 2CTS-1221 |

1200 |

2100 |

19 |

300 |

0-6 |

170-360 |

7.5×2 |

10.8 |

| 2CTS-1224 |

1200 |

2400 |

19 |

300 |

0-6 |

200-390 |

7.5×2 |

11.4 |

| 2CTS-1227 |

1200 |

2700 |

19 |

300 |

0-6 |

230-420 |

7.5×2 |

12.1 |

| 2CTS-1230 |

1200 |

3000 |

19 |

300 |

0-6 |

260-450 |

7.5×2 |

12.76 |

|